Table of Contents

9/10/2014 - Preliminary Bread Molding Research

Author: Julianna Visco (Partner Emogene Cataldo)Cellini

- pane definition

-another better way of casting (81)

Theophilus

-clay molds (132-138, 165 - 182)

-iron molds (67 - 69, 93, 99, 103)

-wooden molds (69, 70, 183)

-cire perdue (106, 132-138, 165 - 182)

-iron mold binding (140, 141, 170)

-bell metal mold?

Cennini

-casting in sculpture (130)

-casting in lead (129)

-casting medals (how to make mold from a coin!) (130)

-box for casting (127, 129)

from JSTOR

- Aesthetics and Alchemy in the Contemporary Kitchen

- joanne molina

- Gastronomica: The Journal of Critical Food Studies

- Vol. 10, No. 1 (Winter 2010) (pp. 145-148)

"In the fourteenth century a recipe in the Secretum Philosophorum turned water into wine by soaking bread in red wine, drying it, and then immersing the bread in water.2"

Quick search of "Arte della cucina:

1 Libri de ricette, testi sopra lo scalco, il trinciante e i vini dal XIV al XIX secolo, Volume 2" on google books, need to go to rare book and manuscript library to see whole thing, anyway did search of "Pane" and found:

-pane dorato (186) golden/gilded

-pane fritte ( 199) fried

-pane grattata ( 310) grated / scraped

9/11/14 - Bread Mold notes/research

Author: EmogeneEEBO/Gallica

I was surprised how difficult it was to scan the manuscripts for the bread molding recipes (for some reason, I had assumed this would be more straightforward). I paged through English and French versions of the Book of Secrets:

Gallica Book of Secrets (French)

EEBO Book of Secrets

All mold entries (except animals) from BnF Ms. Fr. 640

p012r - Pour mouler le soufre/To mold sulfur

p012v - Mouler de stuc promptement/How to quickly mold with stucco

p029r - Stuc pour mouler/Stucco for moldings

p050r - Mouler/Moulding

p053r - Mouler de papier sur cendres chauldes/Molding from paper on hot ashes

p081r - Terre a mouler/Earth for molding

p081v - Gect de chassis/Casting in box mold

p082r - Chaleur de chassis/Heating a box mold

p082r - Chassis/Box mold

p083v - Former de mouler excellente avec eau/Excellent manner of moulding with water

p083v - Moulding one relief side and one hollow side

p089r - Recuire ou essuyer un chassis moule/Reheating or cleaning a box mold

p091r-p091v - Mouler en os de seiche/Molding with cuttlefish bones

p092r - Mouler cave dun coste et de relief de lautre/Molding hollow side and relief

p092r - Mouler statues/Molding statues

p109r - Cire a mouler/Wax for molding

p109r - Mouler cire/Moulding wax

p109r-109v - Serpens a mouler/Molding snakes

p110r - Mouler/Molding

p111r - Recuire les moules/Reheating the molds

p112r - Pour mouler en noyau mixtion du sable/Molding en noyau. Mixing of sand

p113r-113v - Destremper le sable et mouler le premier gect/Wetting sand and molding the first cast

p115r - Recuite de moule/Reheating molds

p115v - Pour donner vent au moule/Venting your mold

p115v - Recuire ses moule a noyau/Reheating core moldes

p116r - Molding boquets of herbs and flowers

p116r - Molding as a core using the same sand for wax images, lead metals, and similar things

p118v-119r - Gect en chassis/Casting in molding box

p119v - Excellent secret to mold hollow and very finely fine gold

p122v - Mouler en creux/Molding hollow

p122v - Molding metals and flat things

p124r - Noyaux pour mouler/Cores for molding hollow

p125v - molding turtles

p126r - Molding fruits and animals with sugar

p127r - Moule de plastre pour cire/Molding wax with plaster

p129r - Roses moulees/Molding roses

p130r - Mouler un yraigne seule/Molding a single spider

p130r - Molding a single vine leaf

p130v -Mouler en chancre/Molding a crab

p130v - Pour mouler tanure/Molding small things

p131r - Ink and molded paper

p131r-131v - Molded wax

p132r - Mold made with two casts

p132r-p132v - Reheating molds

p133r - Clamps and broken mold

p133v - Expansion and little holes in the mold

p133v - Thing that cannot be stripped from teh mold

p134r - Reworking a pierced mold

p142v - Molds

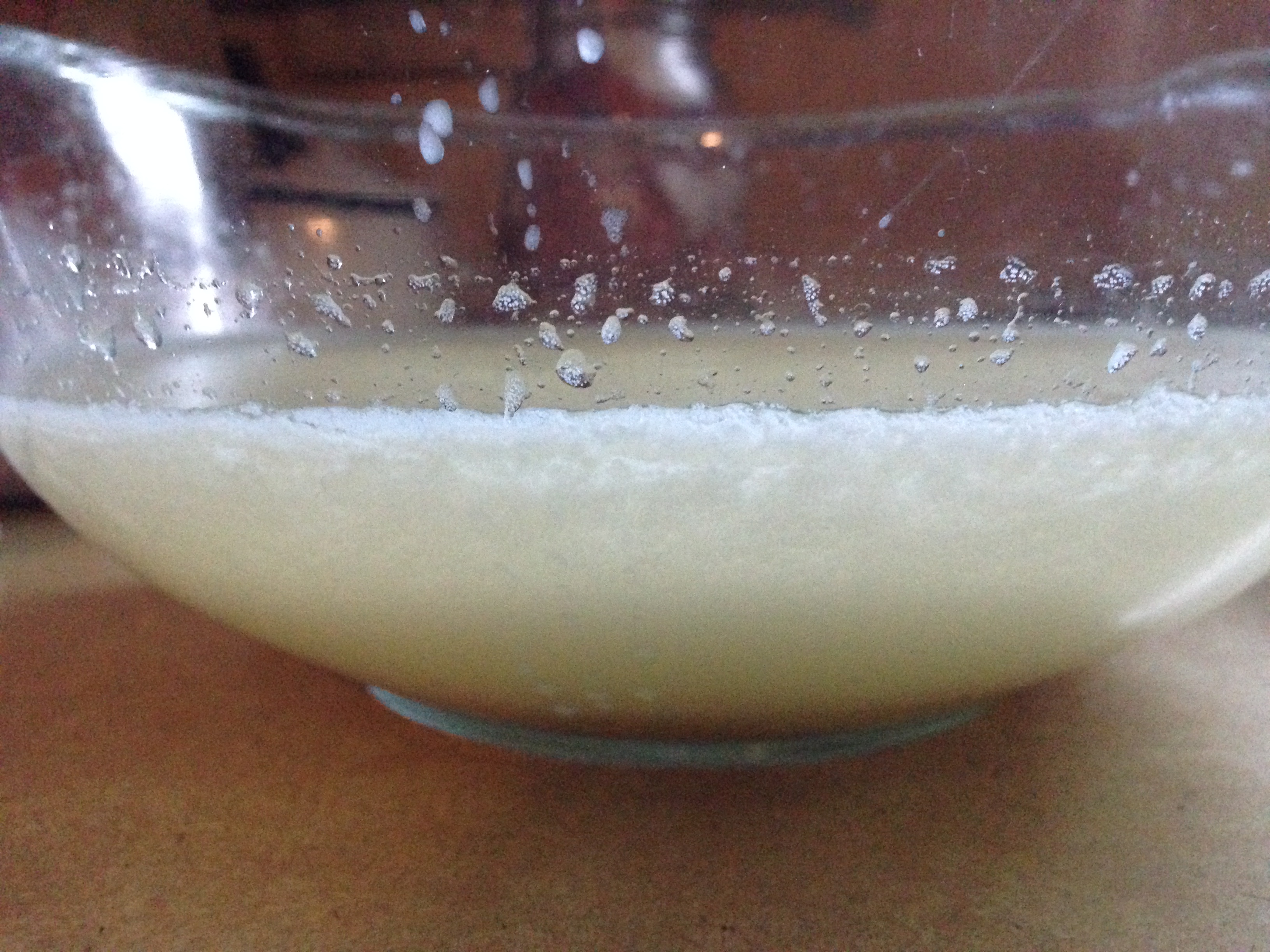

9/13/14 - Sourdough Starter

NAME: Emogene Cataldo and Julianna ViscoDATE AND TIME: 9/13/14, 9:45 AM (updated 2:45 PM)

LOCATION: 142nd Street (Emogene's kitchen)

SUBJECT: Sourdough starter

Author: Emogene Cataldo

In preparation for bread molding, I mixed up a sourdough starter according to a recipe on the blog The Kitchn (using all purpose flour and water):

This is a multi-day process -- today the starter is thick and pasty, tomorrow small bubbles should start to appear and I will need to start feed the starter to keep the yeast from eating in on itself. However, the outside temperature is colder than usual, which may slow the growth of the natural yeast. According to my thermostat, however, it's a comfortable 77 degrees F in the apartment.

A really fascinating article/recipe on sourdough bread from the Splendid Table:

http://www.splendidtable.org/recipes/sourdough-bread-0

Another take on making sourdough bread, with step-by-step video:

http://www.culturesforhealth.com/how-to-make-sourdough-bread

9/15/14 - Notes, Experiments, Tallow

Author: Julianna Visco (partner Emogene Cataldo)Location: at home (springfield, nj, indoors, about 66 degrees)

For possible molding, made a fake medallion out of play-do

1. grabbed fistful of play-doh (old play-doh I found in my closet

2. rolled in out by hand into circle (press on each side to compress)

3. made imprints of varying sizes with 3 objects (a binder clip, a quarter and a led pencil bar)

4. leave out to dry

see images.

Found this link on rendering tallow

http://www.theprairiehomestead.com/2012/02/how-to-render-beef-tallow.html

note: I have a friend who is a butcher – I can see if he can get us enough animal fat to try and make these.

Also this site (below) suggests that kidney fat / kidney suet

makes superior tallow candles but is more expensive. If we are going the route of tallow because it was more affordable perhaps reg. fat will do . .

http://candleandsoap.about.com/od/soapmakingoils/ss/rendertallow_10.htm

9/16/14

Hugh Plat: Casting, Casting with Bread

p. 40 - how to dissolve coral and pearls

p. 41 - the art of molding and casting

(continued on p. 50) ?

BREAD MOLDING - p. 58-59

“Some will molde greate, and curious patternes in the crumme of fine manchet wel tempered into a past, and pressed hard uppon the pattern, some commend flower, and the fat of bacon dissolved, and strayned.”

[to try?]

Casting hollow, p. 64

“If you would cast an egge, or any other patterne hollow thereby both to have your worke the lighter, as also to spare gold and silver, which groweth to be costly in sad workes; then must you line both the insides of the party mold with thin past, made of tough flower, and water onely, and wroughte into an iqual thicknes by the meanes of a rowling pin whose portrature you shalle finde Postea nu. 39. Note also that upon one of the parts of your mold, there must be made a crosse of wire fastened into the molde by turning of the endes of your wire into the same, then lay both the sides of the mold together, each of them having their thin past fitted within, iust with thte circle thereof…"

Manuscript (19 pages):

Hugh-Platt_Casting.pdf

Book of Secrets (EEBO)

Materials for casting, the six "earths"

Earth or sand for casting

Aqua fortis

cuttlefish bones

The true and perfyte practyse to caste medalles;

[warning: rough transcription]

p. 110

Firste of all, you muste have alwayes the earth or sande ready, wherein you wyll fasthy(?) on and fourme youre worke…

other kinds…

so thende that if a manne can not get or make the one, he may evermore have recourse to the other. And understand, that all these that we wyll put here, maye be let a moske(?) eche of them by them selves, or myred one wyth another, or all together, for they are good everye waye. The bountye and perfectyon of eche of these earthes for to caste anye metal in, consp(?)eth in these thynges, that is to wytte: that first and chieflie it be fine and small, and in no wise rough, or full of grommels, to the intent that all thynges maye easely take p(?)pnt. Secondly that they receyve

the mettal well, and that they neyther cleave, breake, chappe, or ware into a cruste. They must also be tempered with a water called Magistra (of the whiche we will speake afterwarde) to the intente that beynge o(?)ye, they may be harder, and holde faster together. Thyrdly, that they may continue, and serve at divers foundinges and melynges, to the intente that whan you wyll caste many metalles, or other thynges all of one forte, ye neede not at every tyme make newe mouldes. Also you muste understande, that for metalles that are softe, as Leade, and Iynne(?), all earth, so it be good, wil suffise: Provided alwayes, that it will be fyne and small, and well tempered with the fayed Magiftra, as I wyll declared hereafter.

"Fyrste earth”

“The second earth or sande”

break pots into pieces (from Valentia in Italy or glassmakers’ pots, new or used)

beat/stamp them into a morter

“The thirde earth, or sande”

take the fylying of yron, sande, or yron ooze(?), or the sparke that flye from hoate yron whan it is beaten or els al together: but that it be pure without anye earth or fylth: than put it in an yron panne, or in some other bessel that wyll enure the fyre, sprinklyng it with strong (?)inaiger, and kepynge it on the fyre the space of eyghte houres, after thys temper it agayne in (?)inaiger, and the incense, and heate it in the fyre, braytnge(?) and renewyng it oivers tymes, as the other. And liepe it in leather bagges, or bores well (?)opped.

“The fyft earth, and the moste parfyt”

take mutton bones, but yfyan take those of the heade, they will be better, if not, take of what part so ever it be, and burne them uppon the coales or in som furneis, until they ware very white; tha stampe them, and sifte them. This doen, you shall put the poulnen…

“The syxte earth”

Take Cuttle bones, and burne them in the fyre, until they be very white, and ofe them in all thinges as you oyo(?) the mutton bones, and than kepe it as afoze. Finally; there is also earth made of the ashes...

Manuscript pages:

Ruscelli_Girolamo-The_secretes_of_the_reuerende_Mayster-STC-295-164_05-p123.pdf

Ruscelli_Girolamo-The_secretes_of_the_reuerende_Mayster-STC-295-164_05-p120.pdf

Ruscelli_Girolamo-The_secretes_of_the_reuerende_Mayster-STC-295-164_05-p119.pdf

Ruscelli_Girolamo-The_secretes_of_the_reuerende_Mayster-STC-295-164_05-p118.pdf

Hildegard and Bread Recipes

NAME: Emogene Cataldo and Julianna Visco (co-authored)

DATE AND TIME: 9/16/14, 11:30 am

LOCATION: Columbia

SUBJECT: Plans for bread baking

The sourdough starter, whose name is Hildegard (named after the saint, whose feast day is tomorrow, Sept. 17), is alive and well after being fed for 4 days. Tomorrow (her feast day) we will bake our first loaves of bread for molds. As we discussed in class today, deciding what recipe to use is a tricky affair, so we will use many over the next week.

Hildegard was created out of regular all-purpose flour, but Julianna will be making some other variations (cousins?) from spelt, rye, or whole wheat. Tomorrow, we're planning to try at least two recipes: one from Ken Albala and the other from the English manuscript that Donna brought in to class today.

Simple Sourdough bread

taken from the Lost Art of Real Cooking (Ken Albala and Rosanna Nafziger Henderson, found via SplendidTable.org)

1 cup starter

1 cup water

pinch of salt

enough flour for a firm dough

knead for 10 minutes

let rise for 2 hours

knock down dough, form it, slash it with razor or sharp knife (to allow expanding)

oven to 550 degrees, or as high as it goes

put ice cubes onto oven floor, let steam build up

transfer dough to preheated pizza stone (will use cast iron pot and some metal pans instead)

bread will rise; double in volume

cook for 20-25 minutes, until crust is golden brown

May, Robert - The accomplish cook or the art and mystery of cookery, p. 239

To Make French Bread the best way

Take a gallon of fine flour, and a pint of good new ale barm or yeast, and put it to the flour, with the whites of six new laid eggs well beaten in a dish, and mixt with the barm in the middle of the flour, also three spoonfuls of fine salt; then warm some milk and fair water, and put to it, and make it up pretty stiff, being well wrought and worked up, cover it in a boul or tray with a warm cloth till your oven be hot; then make it up either in rouls, or fashion it in little wooden dishes and bake it, being baked in a quick oven, chip it hot.

1 gallon flour = 16 cups flour

1 pint yeast or barm = 2 cups

egg whites of 6 fresh eggs, well beaten

3 spoonfuls of fine salt

warm milk and water (to make stiff batter)

9/17/14

Bread Baking and Molding

NAME: Emogene Cataldo and Julianna Visco (co-authored)DATE AND TIME: 9/17/14, 8:30pm (revised 9/21, 5:30pm)

LOCATION:142nd Street

SUBJECT: Bread baking and molding

Bread making commenced at 7am this morning, with the two recipes (English French Bread via Donna and standard sourdough recipe from Ken Albala). The starter (named Hildegard) had just this morning appeared loose and runny.

|

| Sourdough starter on 9/17/14 |

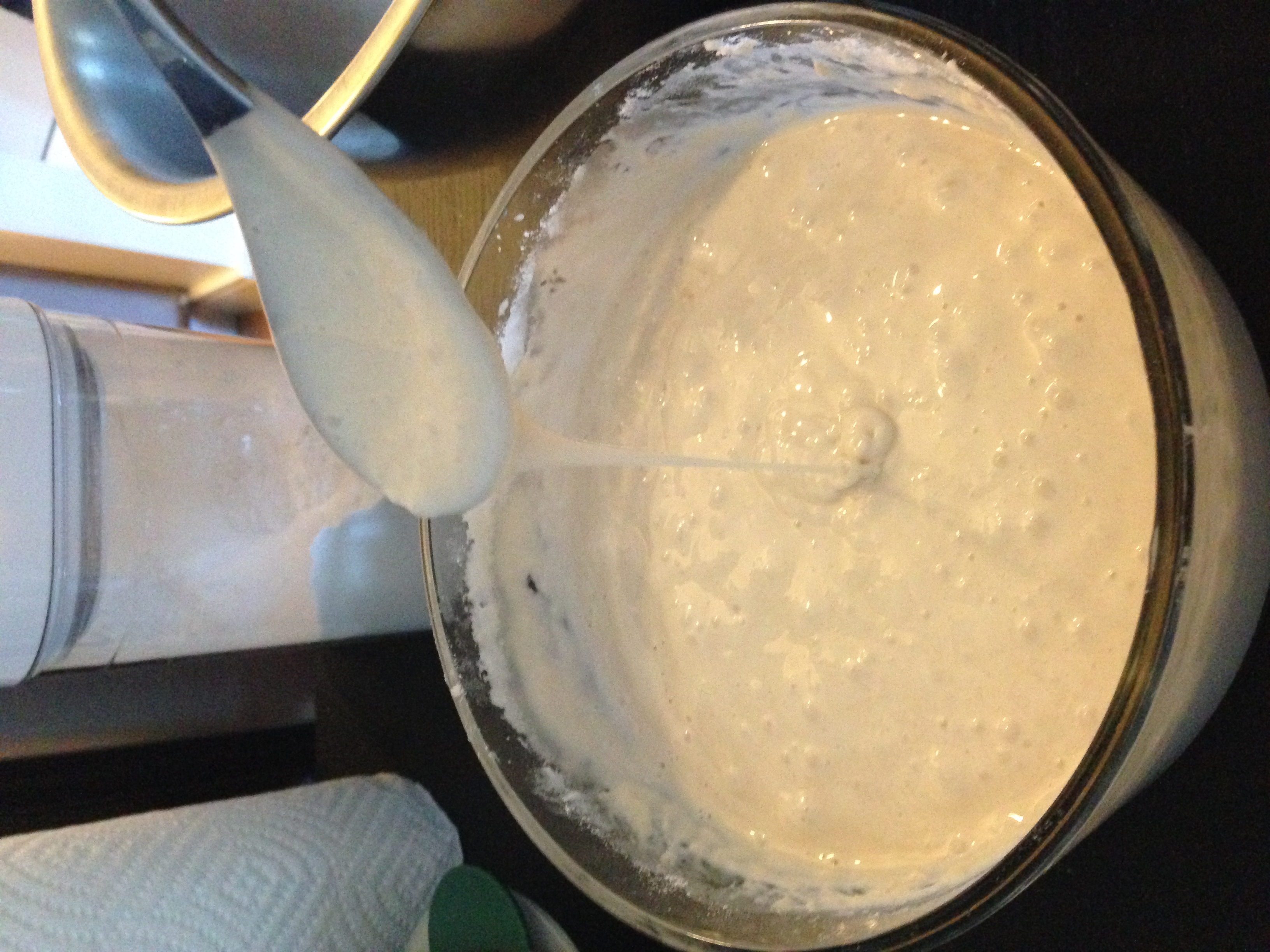

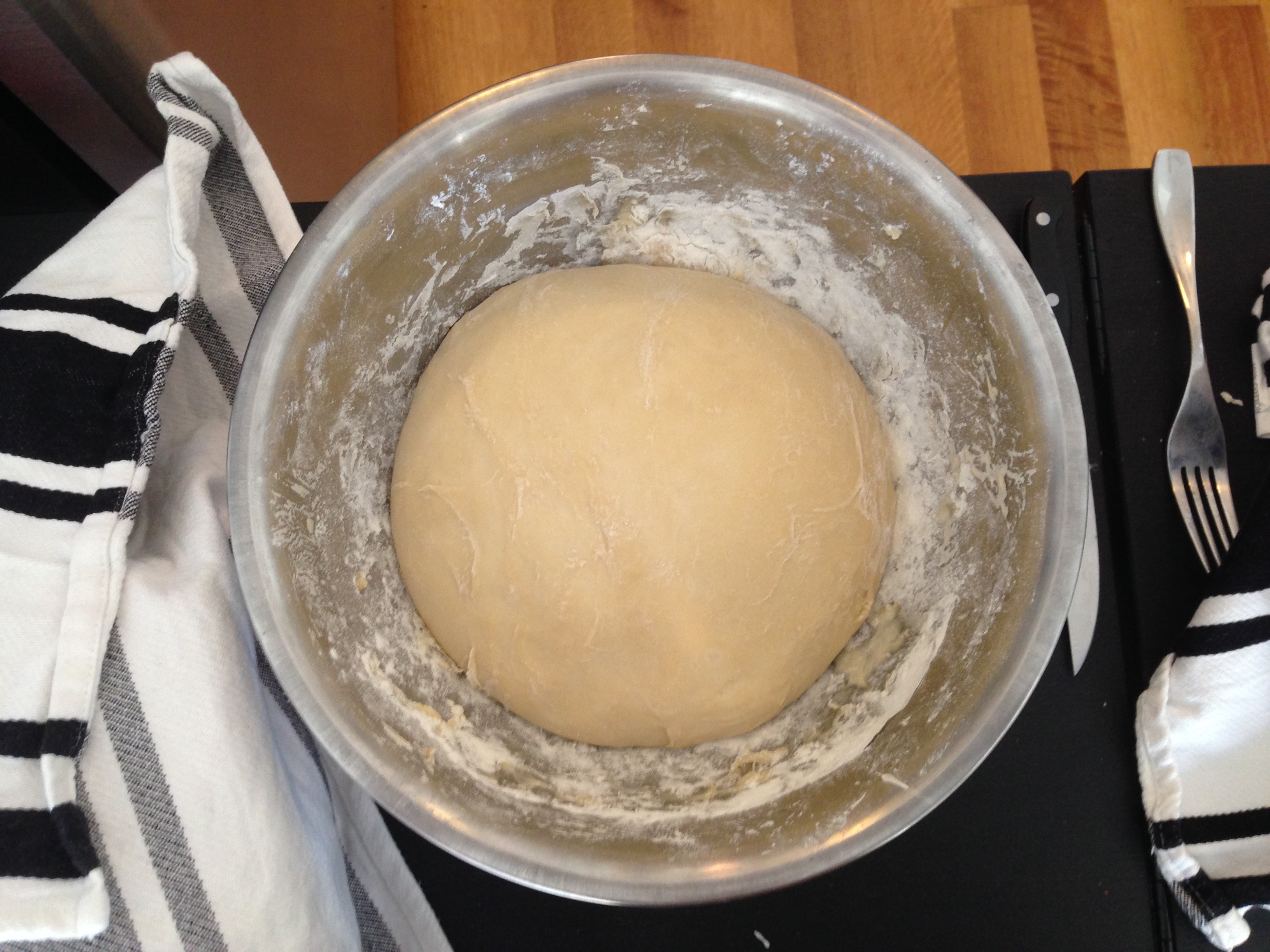

The mixing and kneading of the dough seemed to go rather smoothly---both recipes yielded a fine "stiff" dough. It was difficult, however, to know if either had be kneaded enough, however, and what the exact consistency of "stiff" should be. It wasn't clear if the dough had risen enough.

|

| Albala recipe |

|

| "French" recipe |

|

| Albala recipe, after having risen for 5 hours (punched down once) |

|

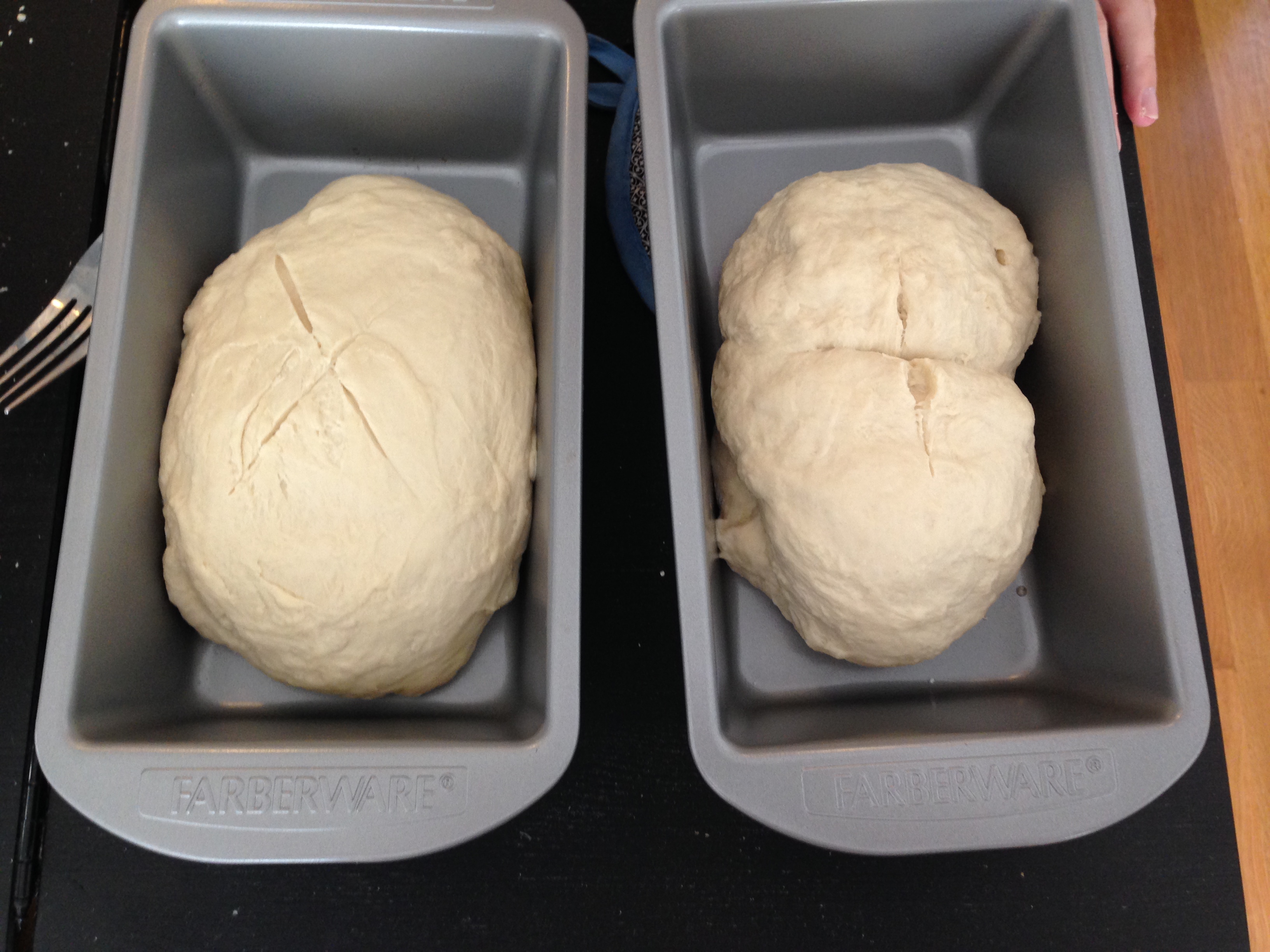

| "French" recipe after 5 hours |

The Albala recipe bread we decided to put in a cast iron pot (not having a "baking stone" on our hands), and the "French" bread was formed into two loaves and put in metal pans. The Albala recipe was sticky (probably not enough flour), so transfer to the pot was very difficult. The "French" recipe transferred much more easily.

|

| "French" loaves |

|

| Albala recipe --- yikes! What a mess. Not our proudest moment. |

We heated the oven as high as it will go (~550 degrees, but I did not have a thermometer to confirm whether my oven is even capable of getting this hot. Each loaf was baked for 25-30 minutes. We put a tray of ice cubes in the oven to build up some steam (a suggestion from Albala), and baked the sourdough loaf in the cast iron pot with the lid on (to preserve steam). Our results were mixed; the Albala recipe, which we had thought to be more predicable, was quite flat and quite dense. From the exterior, the French loaves looked like they had been more "bread"-like: they rose and got a lovely golden brown color on the outside.

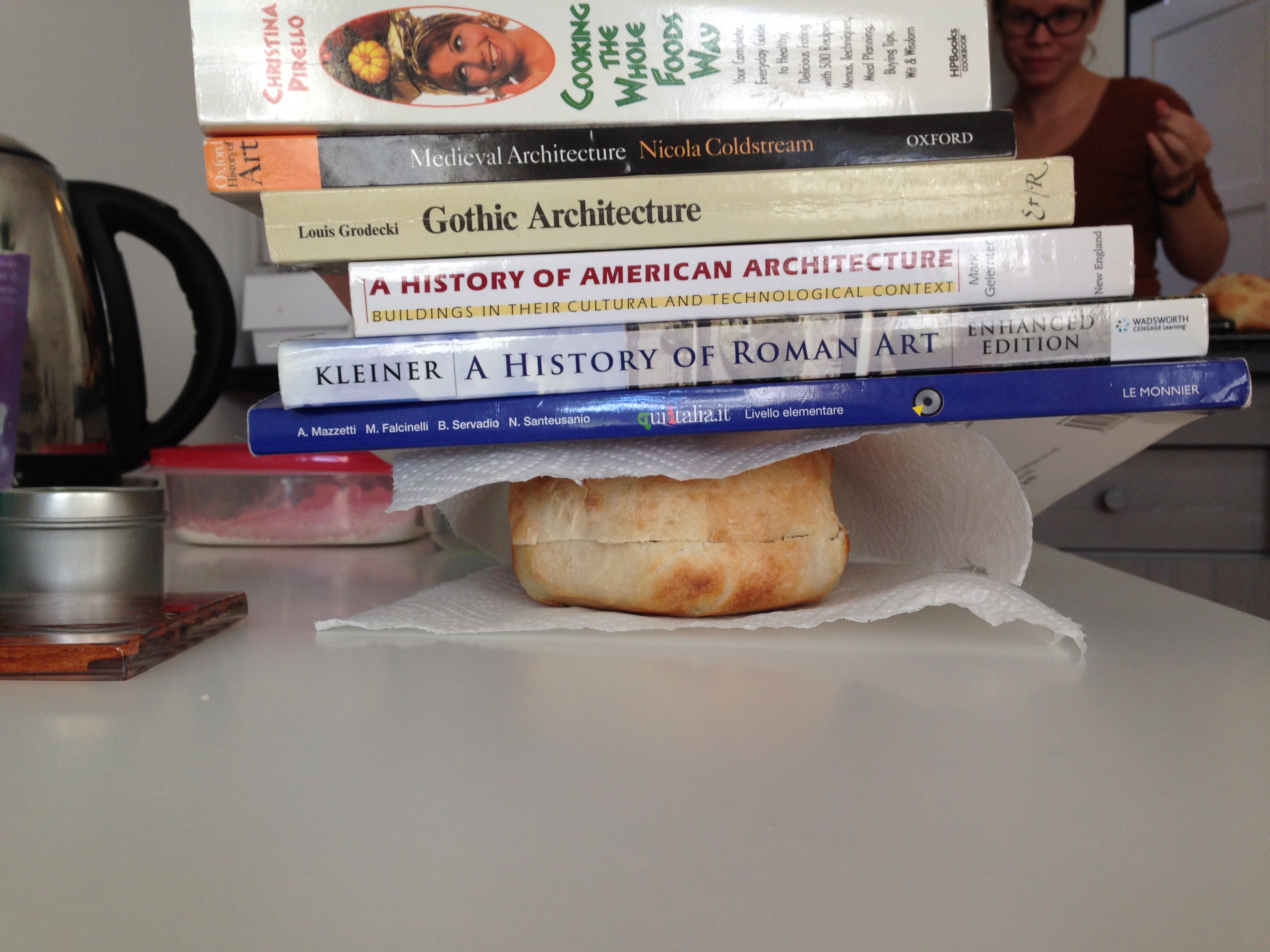

For the molding, we tried two techniques. With the "French" loaves, we cut open the loaves and put the objects directly in the loaf itself, then put the two halves together and let them sit under the weight of several books. For the Albala loaf, we removed the pith from the bread and pressed it around small objects. The bread was still quite hot from the oven when we did this.

The "French" loaf was incredibly dense and soft. If this is the consistency that was intended, it might make a good candidate for a bread mold indeed.

|

| "French" loaf being made into a mold |

|

| With nothing to clamp or bind the mold, we decided instead to weigh it down with books. |

|

| Getting the pith |

|

| Pith molds |

Worried about the freshness of the molds, we did something very inauthentic---we put our molds in the freezer. They will remain here until Monday night, when we will take them out in preparation for class on Tuesday.

More Observations

location: 142nd streetambient: hot - 88 degrees

activity: baking bread

TRIAL RUN

baked 3 loaves of bread

first two (french recipe) in baking loaf pans

third (Donna's recipe) in cast iron pot with lid

temperature approximately 550 F

all baked 25 - 30 minutes

Once removed from oven - let cool 10 minutes. sliced first two loaves in half horizontally, then impressed objects.

we were amazed at how dense french recipe loaf was.

The third recipe baked in the cast iron pot, we removed the crust on the bottom and the skin on top to access the "pith" which we hand molded around several object 1. keyring, 2. plastic key label 3. wrench

while bread baked we had a discussion of bacon fat in Hugh Plat

from

TITLE: The jewell house of art and nature. : Conteining diuers rare and profitable inuentions, together with sundry new experimentes in the art of ....

AUTHOR: Plat, Hugh, Sir.

DETAILS: London, 1594. 245pp.

Full Citation eTable of Contents List of Illustrations

page 59 / image

"molding in crumbs of bread" manchet bread,

search of wikipedia reveals 1588 recipe for manchet bread "The Good Huswifes Handmaide by unknown author"

that particular edition is missing in Clio

More Starters

Author: Julianna Viscolocation : Springfield NJ

temperature: 66 F

Mix up two batches of sour dough starter.

Batch #1 Whole wheat flour

Batch # 2 White wheat flour and spelt flour; ration 1:1

9/18/14 - Starter update

Author: Julianna Viscolocation : Springfield NJ

temperature: 68 F

activity: feed both batches with 1/2 cup each more flour, and 1/2 cup warm (100 F water) stir vigorously

9/19/14 - Starter update

Author: Julianna Viscolocation : Springfield NJ

temperature: 72 F

activity: feed both batches with 1/2 cup each more flour, and 1/2 cup warm (100 F water) stir vigorously

9/20/14 - Starter update

Author: Julianna Viscolocation : Springfield NJ

temperature: 68 F

activity: feed both batches with 1/2 cup each more flour, and 1/2 cup warm (100 F water) stir vigorously

9/21/14

Starter Update

Author: Julianna Viscolocation : Springfield NJ

temperature: 75 F

activity: feed both batches with 1/2 cup each more flour, and 1/2 cup warm (100 F water) stir vigorously

activity: to make tallow : Pick up beef fat at The Pork Store in Union NJ (3 lbs packs, ground)

"French" recipe redux

NAME: Emogene Cataldo (author) and Julianna ViscoDATE AND TIME: 9/21/14, 6:30pm

LOCATION:142nd Street

SUBJECT: "French" recipe redux

After making these recipes, I was wondering if the "French" recipe is really meant to be so dense, and was wondering if making a different shaped bread would result in a different texture.

I remade the same recipe, using the same ingredients, starter, and proportions. Instead of two large loaves, I made seven long loaves---demi baguettes.

Despite this different shape, the bread was still as dense as it was last Wednesday. Makes me wonder if my starter is still quite weak, or if the egg whites should have been whipped more?

This bread is chewy and not bad to taste---it is also very heavy!

|

| demi-baguettes on a tinfoil tray because it's difficult to find cookie sheets that fit in my petite oven |

|

| After baking at ~500 degrees for 25 minutes |

|

| A very dense crust of bread. |

Rendering Tallow

Author: Julianna Visco (partner Emogene Cataldo)location : Springfield NJ

temperature: 75 F

activity: to make tallow

Set crockpot to low. Add 3 lbs of beef fat. Monitor each hour. Total rendering time: 5 1/2 hours

Ladled melted fat into bowl (using two layers of cotton cheese cloth), bits of beef strained out etc.

Let cool overnight in pyrex container covered on counter.

Observation: smell of beef and fat permeates house. I poured small bit of the tallow into a candle holder, adding a wick. If I were to do this again, (for candle not molding purposes, I would add essential oils to mask the beefy smell (reminiscent of elementary school cafeteria in 1980s on cheesesteak or meatloaf day)

9/22/14 - Tallow solidifies

Author: Julianna Visco (partner Emogene Cataldo)location : Springfield NJ

temperature: 66 F

activity: to make tallow

Fat is cooled to room temperature but still quite liquid. Put in refrigerator to try to solidify. Whole kitchen smells 'beefy'.

note: * I have lots of photos but they are not properly loading right now, will try again later

9/26/14 - Tallow Candle

location : Springfield NJtemperature: 72 F

activity:light tallow candle (side effect of tallow experiment)

9/28/14 - Sourdough REDEMPTION

Author: Julianna Visco (partner Emogene Cataldo)location : Springfield NJ

temperature: 72 F

activity:l sour dough REDEMPTION

9/29/14 - Wax models

NAME: Emogene Cataldo (author) and Julianna ViscoDATE AND TIME: 9/29/14, 10:30pm

LOCATION: 142nd Street

SUBJECT: Cleaning of wax model, casting in wax

On Friday we poured wax into our bread mold after the bread had been in the freezer for over a week. The freezer, while historically inauthentic, proved to be an excellent way to preserve the bread without drying it in an oven (hence trying to preserve it as it would have been coming "fresh" out of the oven).

Once the wax had been melted and heated in an enamel pan over a hot plate, we used a paper cut gently bent at the lip to pour the wax into the molds. Our mold held up remarkably well; the wax did not run or spill out from it and the bread captured a surprising amount of detail from our object of choice, an empty ibuprofen bottle.

We let the wax dry completely before attempting to remove it gently from the bread (see video taken during class). Once it was out, the wax model had to be cleaned gently to remove the remaining bread dough from the surface. Since the wax itself is very soft, only gentle tools (wooden spoon, fingers, water) were used. First, I removed the large bread chunks with the edge of a small wooden spoon. Then, I ran the model under running water and cleaned the bread off with my fingers. Finally, I put the model in a water bath and left it for about 10 minutes, afterwards I used my fingers and (very very gently) a fork to clean the bread out of the deeper crevices.

After it had been cleaned, it was amazing to see the amount of detail that had been captured in the model. Even the label covering the body of the bottle left a discernible imprint.

|

| The wax model after hardening in the bread mold |

|

| The water bath was especially effective in helping to get the bread out of small crevices |