Table of Contents

Date and Time: Nov 3- Nov 14, 2015

[Fabrics]

As suggested by Marjolijn, we will test on various materials (cotton, silk, linen) to see how they can be dyed differently.We will first scour fabrics to get rid of oils and starches added in the course of manufacture.

For sourcing fabrics and cleaning materials I find this site useful:

- http://www.dharmatrading.com/fabric/cotton/cotton-fabrics.html

- Fabric shops near FIT are also useful.

For modern manuals, I primarily relied on these sources:

- http://www.wildcolours.co.uk/html/cotton.html#how-to-scour-cotton

- Liles, J. N. The Art and Craft of Natural Dyeing: Traditional REcipes for Modern Use

[Yellow Dyes]

The recipe does not mention specific materials to get yellow. In the BnF, several plants including saffron (038r ,020r, 029v, 041v), weld (010r), lapathium acutum maius(040r), marigold (038r) and dyer's broom are discussed to get yellow colors.But specific procedures to extract dyes are not provided.

From Jo Kirby's book, I learned that both saffron and weld were widely used to dye fabrics, so we've decided to test on these two materials relying on other related recipes.

The Art Conservation Department at the U of Delaware offers useful information on historical dyestuffs (http://www.artcons.udel.edu/public-outreach/historic-art-materials/yellow-dyestuffs). It says saffron "has been prized for centuries as a food

additive as well as its ability to produce a red-yellow dye." For weld, it says "[h]arvested from the Reseda Luteola plant native to Europe, Britain, and the Mediterranean, this dyestuff produces an intense yellow when combined with an alum mordant.

Copper mordants can also yield a green color and iron, a green-yellow. Weld has been used since ancient times and is often combined with other dyestuffs such as woad and indigo to create a range of greens heading towards blue. It has also been

used as an ink (dissolved in alcohol) and can be found in medieval paintings and manuscripts." According to the BnF, saffron seems to have been used for coating as well.

We've purchased saffron from a local Indian food market.

We've purchased dried weld from here: http://earthues.com/natural_dyes/raw_materials

1. First Option: Saffron

Related Recipes: ON THE CHARACTER OF A YELLOW CALLED SAFFRON. CHAPTER XLVIIII (from Cennini)

A color which is made from a herb called saffron is yellow. You should put it on a linen cloth, over a hot stone or brick. Then take half a goblet or glass full of good strong lye. Put this saffron in it; work it up on a slab. This makes a fine color for

dyeing linen or cloth. It is good on parchment. And see that is is not exposed to the air, for it soon loses its color. And if you want to make the Most perfect grass color imaginable, take a little verdigris and some saffron that is, of the three parts let

one be saffron; and it comes out the most perfect grass-green imaginable, tempered with a little size, as I will show you later.

Historical Context of Saffron (from Merrifield)

(pg. clxv) Saffron, zafferano, the crocus of the middle ages, is produced from the flowers of the crocus. Peter de S. Audemar informs us that saffron was produced in France in his time; but he says the French saffron was not good; he mentions that

this drug was imported from Spain and Italy, and that the best kind was brought from Sicily, and was called corsicos. The plant is cultivated extensively in England in the neighbourhood of Saffron-Walden, and the name of the place is derived from

this circumstance...

Historical Context of Saffron (from BnF)

<id>p038r_2</id>

<head><m>Saffron</m></head>

<ab>It is imitated and increased with half dried marigold leaves, twisted like a thread, and dried in the hottest sun, and this is mixed, and the aforementioned marigold even adds some dye.</ab>

Questions

- What's the use of lye in Cennini's recipe?

Does it serve as a mordant agent? According to Jo Kirby, saffron is one of the plants that do not require mordants. Then what is the purpose of lye?

Lye was widely used to bleach linen. Was it used for that purpose in this recipe?

http://www.ukessays.com/essays/sciences/looking-at-the-history-of-bleaching-science-essay.php

- Do we not boil the lye? We will get to add some heat any way by following the recipe. We will see how it goes.

- I've decided to make lye using a modern recipe.

- The recipe does not specify quantity info. I will use saffron in the amount of 4 % of fabrics. See

A review of the chemistry and uses of crocins and crocetin, the carotenoid natural dyes in saffron, with particular emphasis on applications as colorants including their use as biological stains

2. Second Option: Weld

I found a recipe from Jo Kirby's book. I am working on the protocol now.

[Blue Dyes (to make green)]

There's one related to recipe on woad but this one does not specify how to process (ferment) it.Related Recipes for Woad (from the Bnf)

<id>p039r_2</id>

<head><m>Dyers woad</m></head>

<ab>It is grown in <pl>Auragnes</pl> where the soil is so fertile that if you grew wheat there

every year, it would fall over from the kernels being too full. This is why <m>dyers woad</m>

and wheat are cultivated alternately. For cultivating </m>dyers woad</m>, the soil is ploughed

with <m>iron</m> shovels like those of gardeners. Then with rakes, clods of earth are broken

up and tilled as for the sowing of some vegetable gardens. It is usually sowed on Saint

Anthony’s day in January. Eight harvests can be made. The first ones are the best. The best of

Auragne’s <m>dyers woad</m> is the one from <pl>Carmail</pl> and the one from

<pl>Auraigne</pl>. And sometimes the <m>dyers woad</m> is good in one field and worthless

in another that is closeby. The quality of the <m>dyers woad</m> can be recognized when you

put it in your mouth and it tastes like vinegar, or when you crumble and break it, there are silver

or golden moldlike veins. It is pressed in the dyers’ cistern, and to fill a cistern, six bales are

needed. Several <m>wool</m> flocks are kept there. And if it produces 15 dyings, it is said to

be worth 15 florins, if it produces 20 dyings, 20 florins. The good kind will dye up to 30 times and

usually up to 25 or 26.</ab>

</div>

Other recipes for reference

1) Recipes in German(?) from the Database on Colour Practice and Knowledge: https://arb.mpiwg-berlin.mpg.de/node/81566

2) Translated from the French manuscript in 1816 and provides a detailed account on how to extract indigo from woad (and a lot of useful information on the historical context of woad). Lasteyrie, C. de (Charles). A treatise on the culture, preparation,

history, and analysis of pastel, or woad; the different methods of extracting the coloring matter, and the manner of using it, and indigo, in dying. To which is added, information upon the art of extracting indigo, from the leaves of pastel ... Translated from the French, by

H.A.S. Dearborn. Boston, 1816.

(http://find.galegroup.com.ezproxy.cul.columbia.edu/mome/eToc.do?inPS=true&prodId=MOME&userGroupName=columbiau&tabID=T001&searchId=R1&searchType=AdvancedSearchForm&contentSet=MOMEArticles¤tPosition=1&showLOI=}&docId=U3603328125&docLevel=FASCIMILE&workSubLevel=ETOC&workId=19010212200800&action=DO_BROWSE_ETOC&&collectionId=ocm16893196&relevancePageBatch=U103328021&totalCount=1&sort=DateAscend&doDirectDocNumSearch=false)

Related Recipes for Making Green out of Blue and Yellow (from the BnF)

p032v_1Mat Makers

Two kinds are made in Toulouse, one to cover rooms’ walls which are finely woven, almost like straw hats worn by villagers, and are made in long rolls, some 10 straws wide, others 13. And they work on them mainly in summer and winter. Then when they prepare it they sew it, but beforehand they dye it in usually three colours: green, red and sometimes purple. The green one is made with only a pastel tincture since green is made from yellow and blue, so the pastel dyes the dark yellow straw. It becomes bright green. For red they use some alum and brazil wood, for purple they use pastel and some coperous which darkens blue with its black tincture.

p037_2Glass-maker Some do not lay gris d’escaille on the glass to work on it, but trace straight on the glass with noir à huile. However, it is important that the wood be degreased, because if it has even a little grease [on it], the color will not take at all. And even, if the working glassmaker has a stink from his nose or his mouth, and he breathes on the glass, the color will not take on it. Those who came up with the invention of working in small works of softened enamels use only azure enamel, which is blue, and esmail colombin, which is the color of purple, which they soften with rocks or lead glass. As for yellow, they make it from silver, red from sanguine, as is said elsewhere, black and gray and shadows from scale black, either strong or weak, carnation from light sanguine. Green is made first from yellow, then they overlay azure enamel, either strong or weak, depending on whether they want to make it bright or dark.

Sourcing Woad

We have three options: woad leaves, woad balls, and extracts.

1) Woad leaves: It would be ideal to begin with extracting indigo from freshly harvested woad leaves, but the thing is that it is too late to get good-quality leaves (best-quality leaves are generally harvested in summer). I talked to a couple ofexperts(practitioner) of woad dyeing in the US and UK, and both of them are negative about this idea, although the UK expert said it might be worth trying given that this fall has been pretty warm. But again, it seems that there's no woad growers around NYC or even in the US. I talked to the dealers that Cindy mentioned, but they rely on imported woad extracts (one from France).

2) Woad balls: If we have to jettison the woad leaves option, this might be the best. It is a kind of semi-processed woad leaves, and I've found one supplier online:https://www.etsy.com/listing/232697812/woad-ball?utm_source=google&utm_medium=cpc&utm_campaign=shopping_us_a-craft_supplies_and_tools-fiber_and_textile_art_supplies-other&utm_custom1=1e7daaa6-48c2-4560-9c1c-b37b96415c15&gclid=CjwKEAiA3_axBRD5qKDc__XdqQ0SJAC6lecAsLD3xPJpD9egKFvdXRiXvnMKOc4iprRgr7T2xXsQCRoCl8jw_wcB

The American woad expert said that woad balls might be a good option if we can source one. The product in the link is imported from England.

It seems that making woad balls was a common practice to circulate woad at that time. It was briefly mentioned in a document that had noting to do with dyeing: http://eebo.chadwyck.com.ezproxy.cul.columbia.edu/search/fulltext?ACTION=ByID&ID=D40000998954330418&SOURCE=var_spell.cfg&DISPLAY=AUTHOR&WARN=N&FILE=../session/1446870243_17998

3) Extracts: There are abundant suppliers so we should not worry about sourcing this. I confirmed with Kremer that their woad extracts are intended for dyeing, but Cindy was told differently! Anyway they don't have stock right now.I know that the sourcing plan needs to be finalized by this Monday but I would like to finalize it with other faculty members that day and then proceed (if we go for balls or extracts, or both?).The American expert cautioned that blue color one can get from woad leaves can be very different from that of extracts. Extracts are much stronger. While the BnF recipe does not specify the process for extracting, the treatise above does.I am not sure if it is because the method for circulating woad has been changed or simply the BnF did not talk about extraction.

Whatever source we use, we won't be able to follow the traditional fermentation method, which needs to be done in summer requiring a space between 35 C and 43 C. We will have to rely on a chemical method like this:

http://www.woad.org.uk/html/chemical.html We were not able to source any fresh woad leaves (it's already mid-Nov), so we will test with woad balls and extracts.

[Question 1: What is "damask cloth"?]

I consulted several dictionaries.Dictionary of Textiles by Louis Harmuth in 1915:

1) "originally a rich silk fabric ornamented with colored figured often in gold or silver; 2) an all-worsted twilled fabric made in England in the 18th century; 3) the true or double or reversible damask is woven both the ground and the large floral

Jacquard patterns in eight-leaf satin and the single damask in five-leaf satin weave. Single damask is also made with figures, not in satin but plain or twill weave. Usually made of cotton or linen and used on the table."

Fairchild's Dictionary of Textiles by Stephen S. Marks in 1959:

"Originally a rich silk fabric with woven floral designs in China and introduced into Europe through Damascus, from which it derived its name...Damask has been made for centuries and is one of the oldest and most popular staple cloths.

Used for upholstery and draperies, table cloths, napkins, bedspreads, face towels, evening wear, etc."

http://babel.hathitrust.org/cgi/pt?id=wu.89043757574;view=1up;seq=181

101 Fabrics: Analyses and Textile Dictionary by J. J.Pizzuto in 1952:

" 1) Table Linen: A fabric with an elaborate Jacquard design. It has a warp face satin weave for the pattern and a filling face weave for the ground. For table linen, single damask is made with a five harness satin weave, double damask

with an eight harness satin weave: usually made of linen but may be made of cotton or rayon. 2) Drapery or Upholstery: Elaborate fabric in satin or satin or twill weave combination; woven in dobby or Jacquard patterns.

The fabric is made with long floats which form the pattern. Fabrics are soft lustrous, and drape well. Cotton, silk, or rayon may be used. The yarns are usually single in the warp, and single, plied, or novelty in the filling. 3) Ticking: Elaborately

designed, Jacquard woven fabric with warp and filling satin weave floats of contrasting colors. This fabric is used for mattresses and may be made of cotton , or rayon and cotton"

http://babel.hathitrust.org/cgi/pt?id=mdp.39015021215481;view=1up;seq=134

From the sources above, damask generally means patterned woven fabrics intended for interior decoration.

But these sources were all published in the early 20th century. Further research on the history of damask in the 16th century will be required.

Meanwhile, I searched "damask" "made between 1300-1700" on the website of V&A museum.

http://collections.vam.ac.uk/search/?listing_type=list&offset=0&limit=45&narrow=1&extrasearch=&q=damask&quality=0&objectnamesearch=&placesearch=&after=1300&after-adbc=AD&before=1700&before-adbc=AD&namesearch=&materialsearch=&mnsearch=&locationsearch=

As described in the dictionary definitions above, most searched items were patterned, woven fabrics made of silk or linen. There was no cotton damask.

Unlike Italy, where a good number of damask fabrics made before 1600 were searched, most damask items from France were produced after 1600. I am not sure whether this could tell us something about weaving technology in France and the status

of damask in its fabric market at that time.

On the website I also found a concise definition of damask:

"a woven material whose effect depends on the differing play of light on its pattern surfaces, which alternate between the smooth face and the contrasting reverse of satin weave."

http://collections.vam.ac.uk/item/O82549/dolls-undress-gown-unknown/

In other words, unlike other types of weaving that make patterns using different colors of threads for warp and weft, damask create patterns using identical colors for warp and weft. Its patterns are created by difference in luster rather than color.

The this definition is not used consistently on the V&A website.

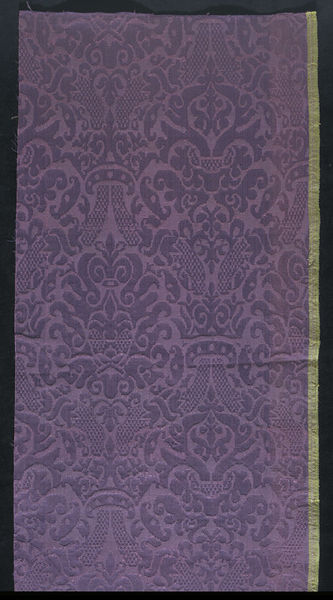

Below is silk damask made in Italy between 1600-1650. Intended for furnishing fabric

http://collections.vam.ac.uk/item/O225682/furnishing-fabric-unknown/

|

| external image 2006AN1113_jpg_l.jpg |

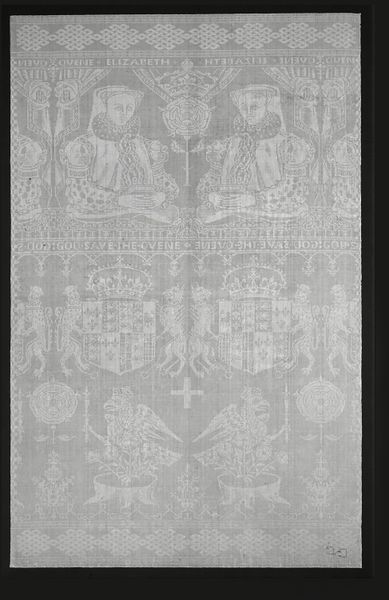

Linen damask napkin made in Flanders between 1570-1600. The annotation says the highest quality linen was woven in the Southern Netherlands.

http://collections.vam.ac.uk/item/O101377/napkin-unknown/

|

| external image 2013GA8805_jpg_l.jpg |

So are these what the author meant by "drap damasse (damask cloth)"?

I looked up the term in several dictionaries.

Dictionarie of the French and English Tongues by Randle Cotgrave in 1611.

"Drap" means cloth; woolen cloth; broad cloth

It did not have "damasse"

The Royal Dictionary. French and English. English and French by Abel Boyer in 1729.

"Drap" meant woolen cloth.

Again, there was no "damasse"

I've found "damasse" in Dictionary of Textiles by Louis Harmuth in 1915.

It means: 1) French shawl, made with combed wool warp and filling with large flower designs; 2) French for fabrics having both the ground and the large patterns woven in satin weave but of various colored or lustered yarn; 3) in French general term

for fabrics woven on a Jacquard loom.

The second definition of "damasse" is close to the definitions of damask discussed above.

In summary, it can be said that "drap damasse (damask cloth)" is woven, patterned fabric. Extant artifacts tell us that it is mostly made of linen and silk but as seen from the definition of "drap" there is also a possibility of woolen cloth.

[Question 2: What is "Moorish shapes"?]

I searched "moresque" "between 1350-1750" "made by damask technique" on the V&A website, which yielded only one result:

http://collections.vam.ac.uk/item/O264602/woven-silk-unknown/

It was woven using more than three colors, which contradicts the site's definition of damask.

|

| external image 2009CR5268_jpg_l.jpg |

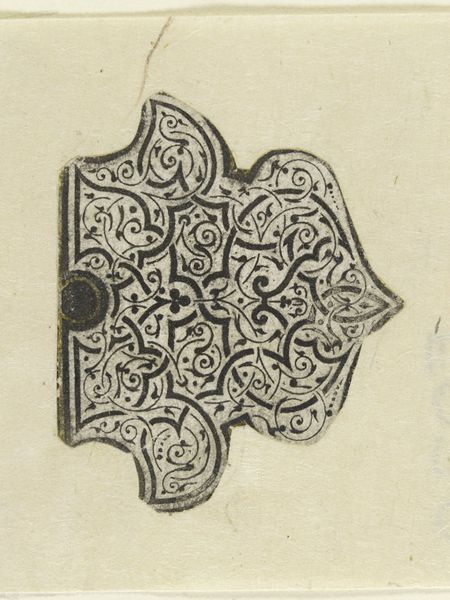

I again searched "moresque" "between 1350-1750" "made in France."

It did not show any textile items but instead numerous prints for ornament such as this:

http://collections.vam.ac.uk/item/O755213/print-anonymous-engraver/

The annotation says it was "a design for goldsmith's ornament containing a Moresque design," made in France between 1510-1551.

It tells us that Moresque designs were circulated among French artisans for making various sorts of crafts.

|

| external image 2011FB4815_jpg_l.jpg |

Another print. http://collections.vam.ac.uk/item/O755212/print-anonymous-engraver/

For our experiment we could possible use one of these patterns.

|

| external image 2011FB4816_jpg_l.jpg |