Name: Kathryn Kremnitzer, Siddhartha Shah

Date and Time:

2015.10.19

Location: Lab

Subject: Red Lake Pigments

We began preparing ingredients necessary for the recipe at 9:00am

Preparation:

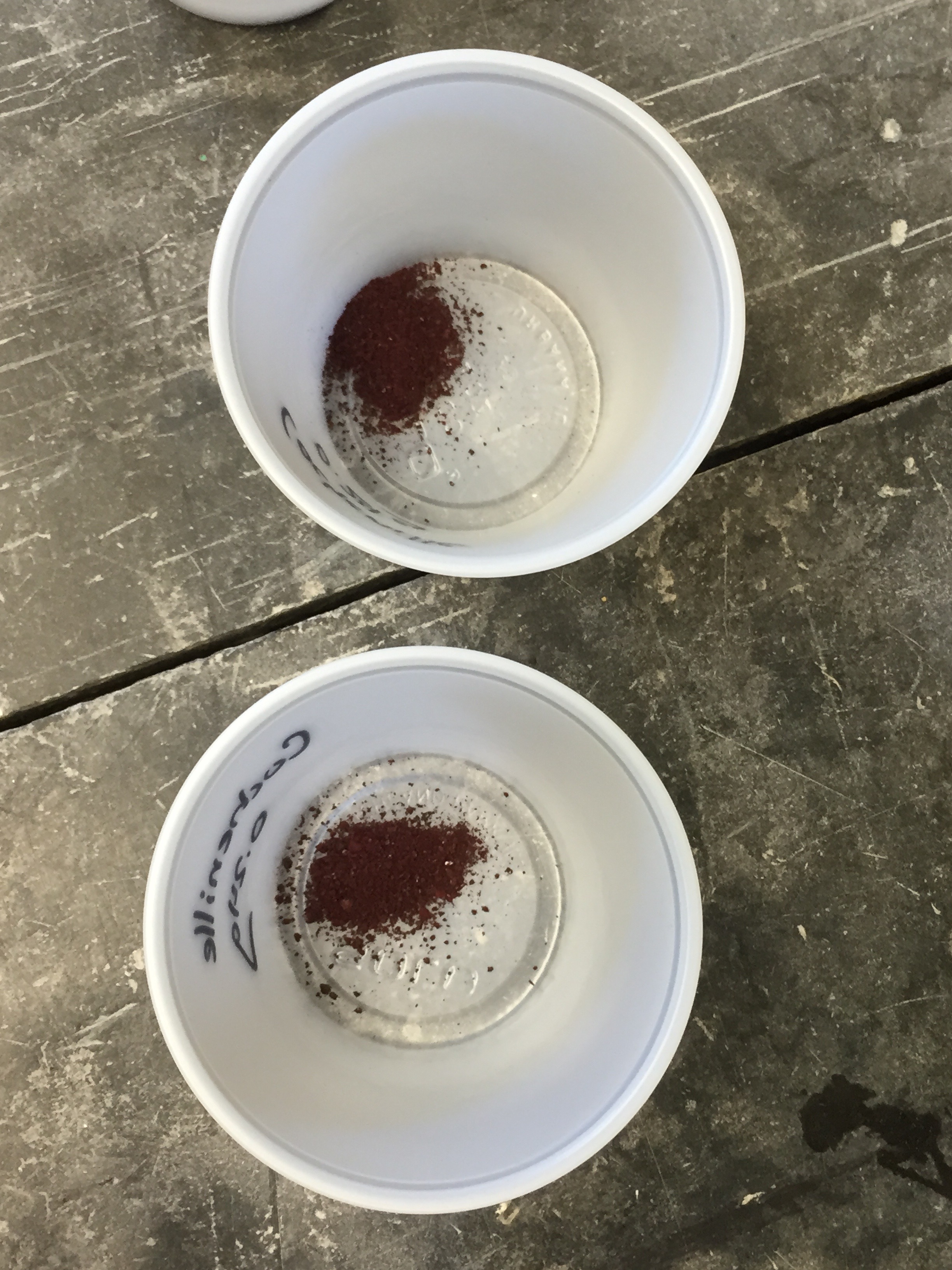

- Weighed 1.5g of cochineal in small plastic cup before grinding

- Ground cochineal in small marble mortar with marble pestle

- Divided 1.5g of cochineal into six containers of 0.24g each

- Crushed four additional insects in fear of not having enough ground cochineal to fill 6 containers

- Weighed 10g of logwood in small plastic cup

- Weighed 10g of brazilwood in small plastic cup

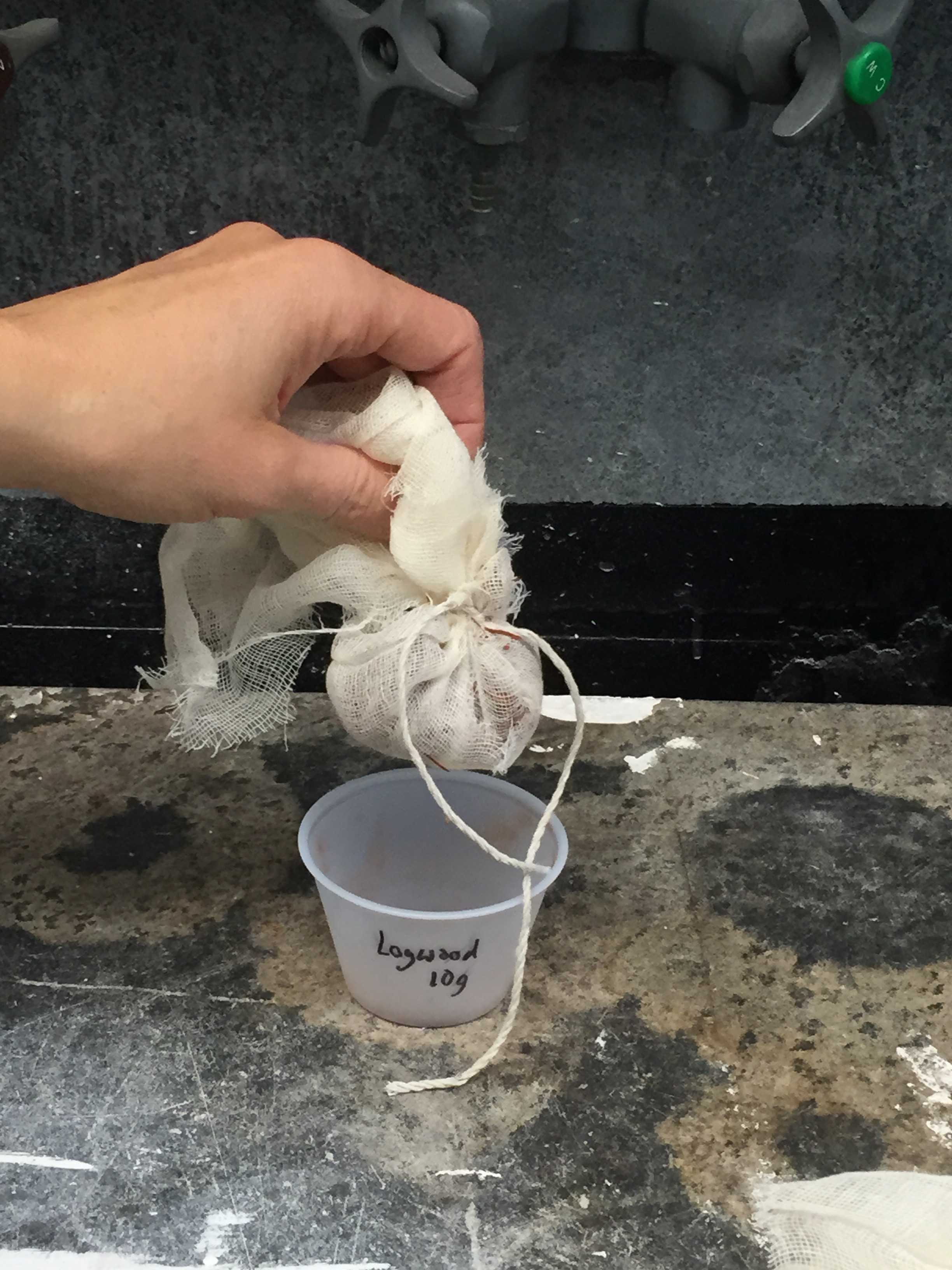

- Put logwood in double lined cheesecloth sachet, tied with twine

- Put brazil wood in quadruple lined cheesecloth sachet, tied with twine

9:47am

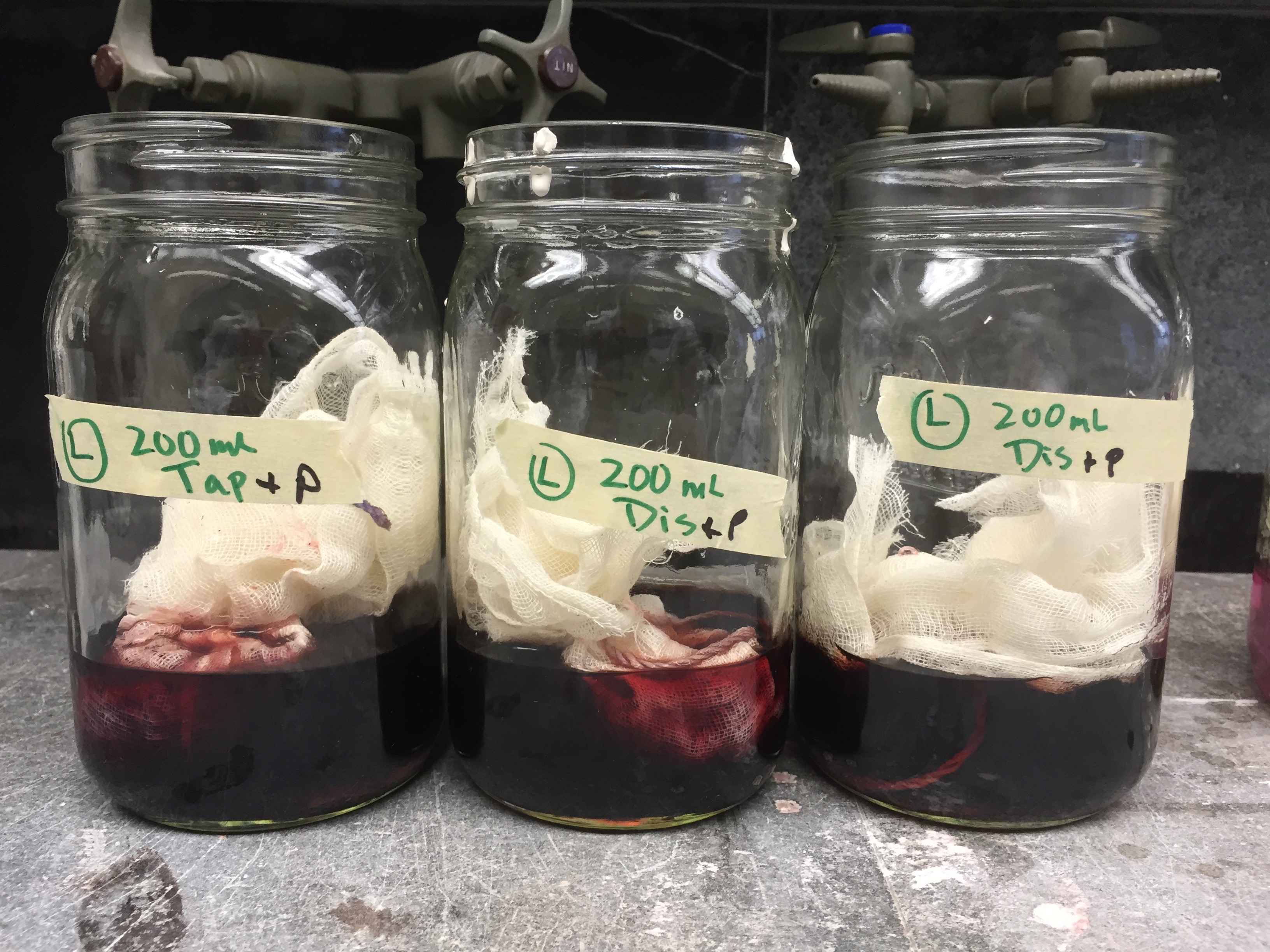

Put two sachets of logwood in separate beakers of 200 ml of distilled water and potash and one sachet of logwood in a beaker of 200 ml of tap water and potash, used spoon initially to submerge logwood

9:47am

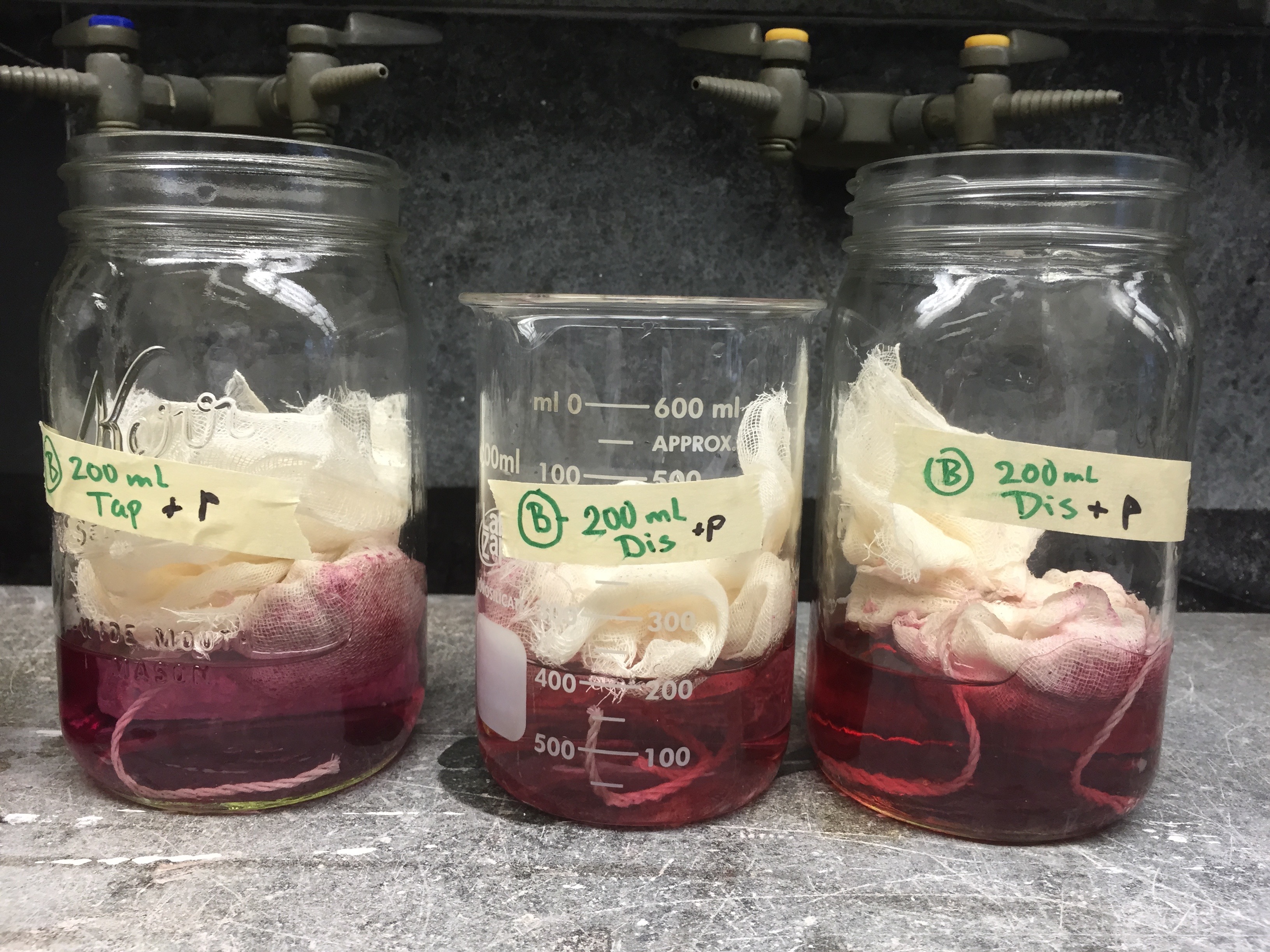

Put two sachets of brazilwood in separate beakers of 200 ml of distilled water and potash and one sachet of brazilwood 200 ml of tap water and potash, used spoon initially to submerge brazilwood

9:53am

Soaking logwood is significantly more blood red than rather aqueous looking than soaking brazilwood

Setup of Stations:

CD: cochineal distilled

CT: cochineal tap

BD: brazilwood distilled

BT: brazilwood tap

LD: logwood distilled

LT: logwood tap

Station 1:

CD

BD

Station 2:

CD

BD

Station 3:

CD

BT

Station 4:

CD

LD

Station 5:

CD

LD

Station 6:

CT

LT

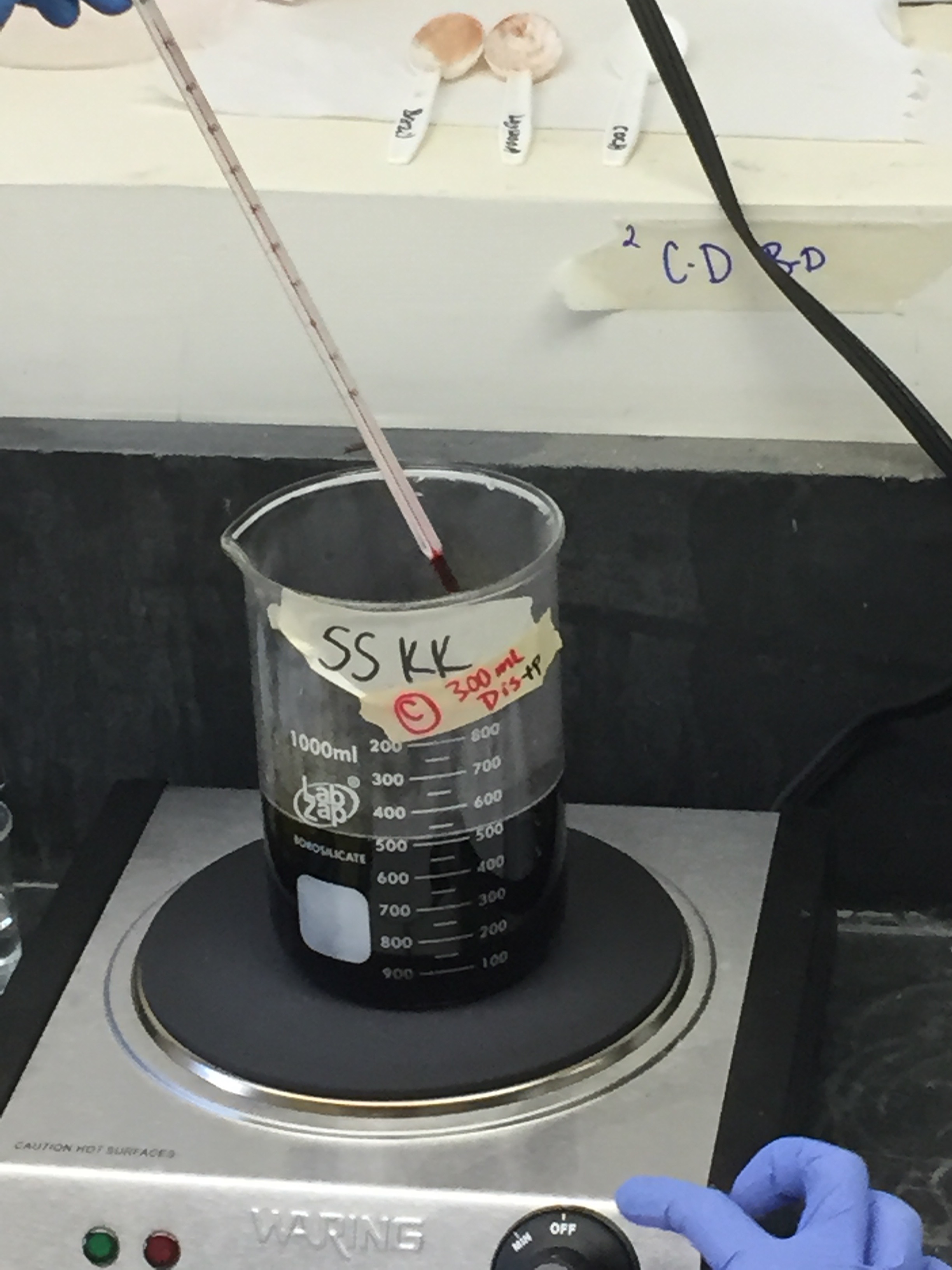

SS/KK – STATTION 2 (CD, BD)

9:47am

Soaking sachet of brazilwood in 200ml of distilled water and potash (need to soak for 2 hours)

10:18am

Put 0.24g of cochineal into large jar of 500ml distilled water and 300 ml of 0.1 M potassium carbonate (K2C03) solution [potash]

10:20am

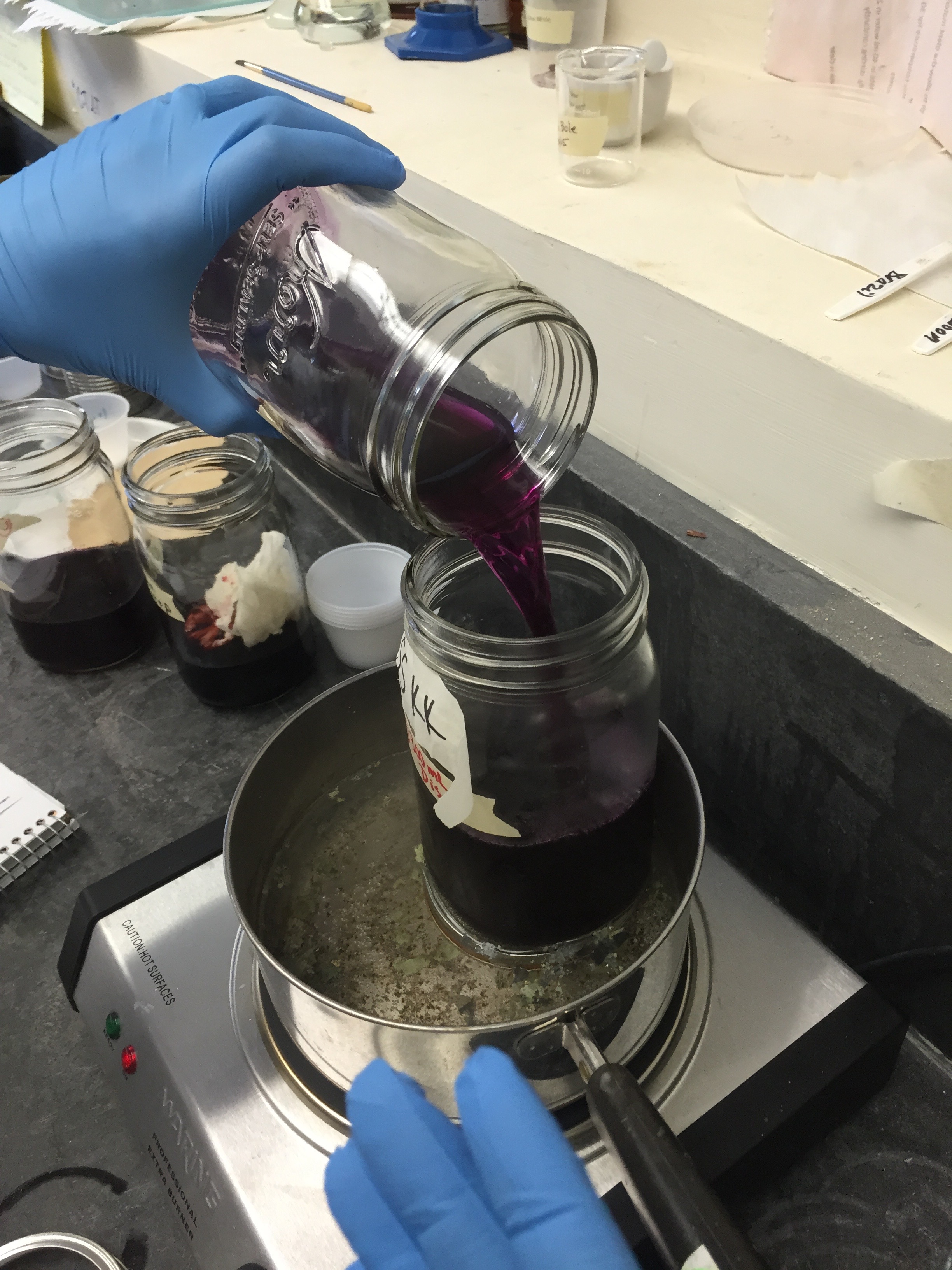

Put jar on lid in water bath on hot plate set at 3

10:25am

Discussion about what to do and pros/cons of shared substance re: time it takes to boil but we didn't transfer anything

Turned burner up from 3 to 5 following PS instructions to get it to boil

10:26am

Combined Cindy and Yuan’s solution with SSKK solution (will have to re-separate the solutions into 300ml each)

10:27am

Switched water bath water out (debris in previous pot) - starting over (re: boiling) although water is not cold

10:32am

Dissolving 10g of potash in 50 ml of distilled water WITHOUT heating for now

10:35am

Cochineal solution is 38 degrees Celsius

10:37am

Potash is not dissolving in distilled water without heat.

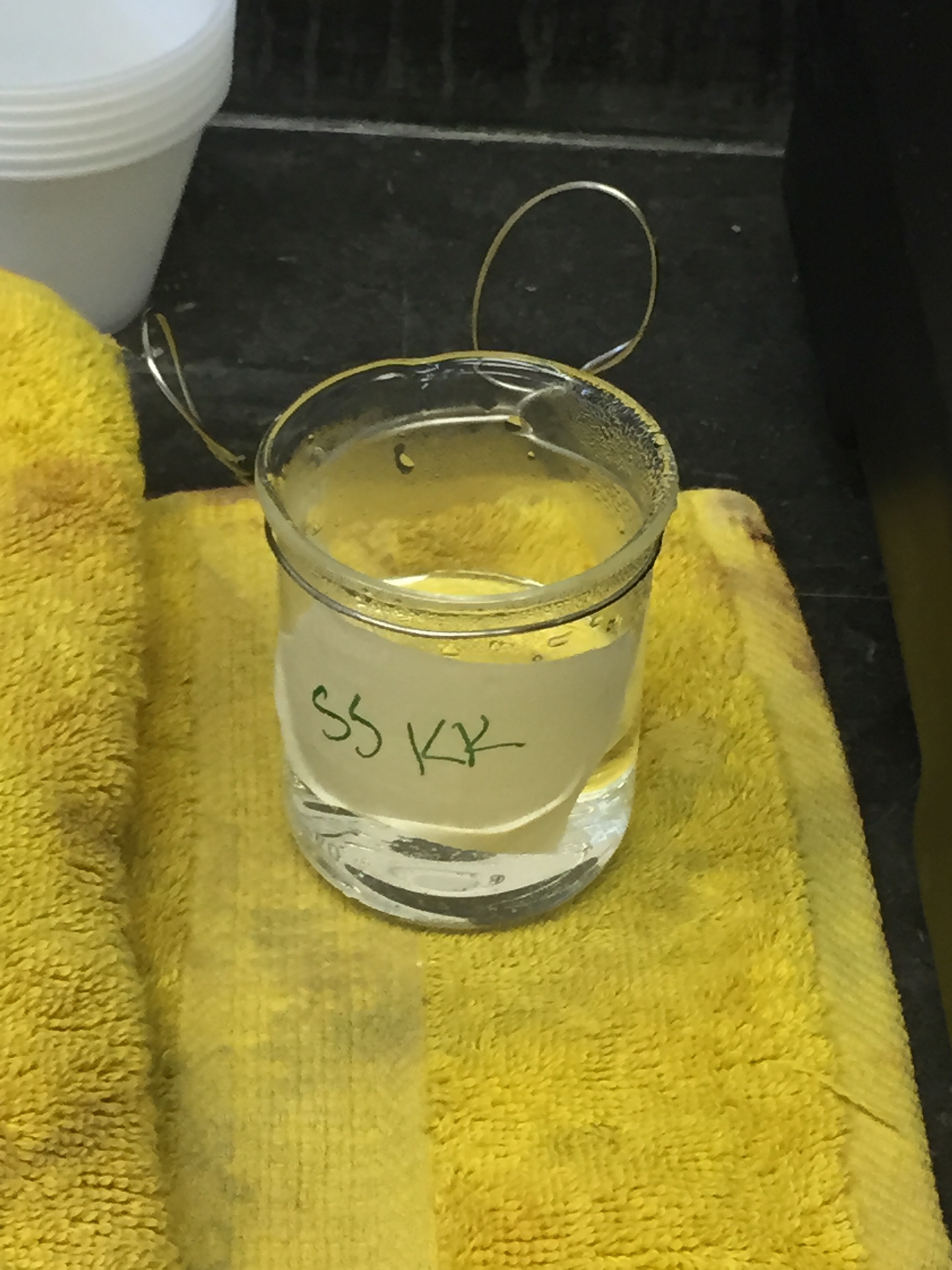

Dissolving 10g of potash in 50 ml of distilled water over heat suspended in water bath by wire system held with two fingers

10:41am

Cochineal solution is at 54 degrees Celsius

10:41am

Potash is almost dissolved in water

10:42am

Reduced heat to 3.5 (after a certain point at 5, the temperature seems to blast, so we decided to reduce)

10:43am

Potash is dissolved, we are setting solution aside

10:44am

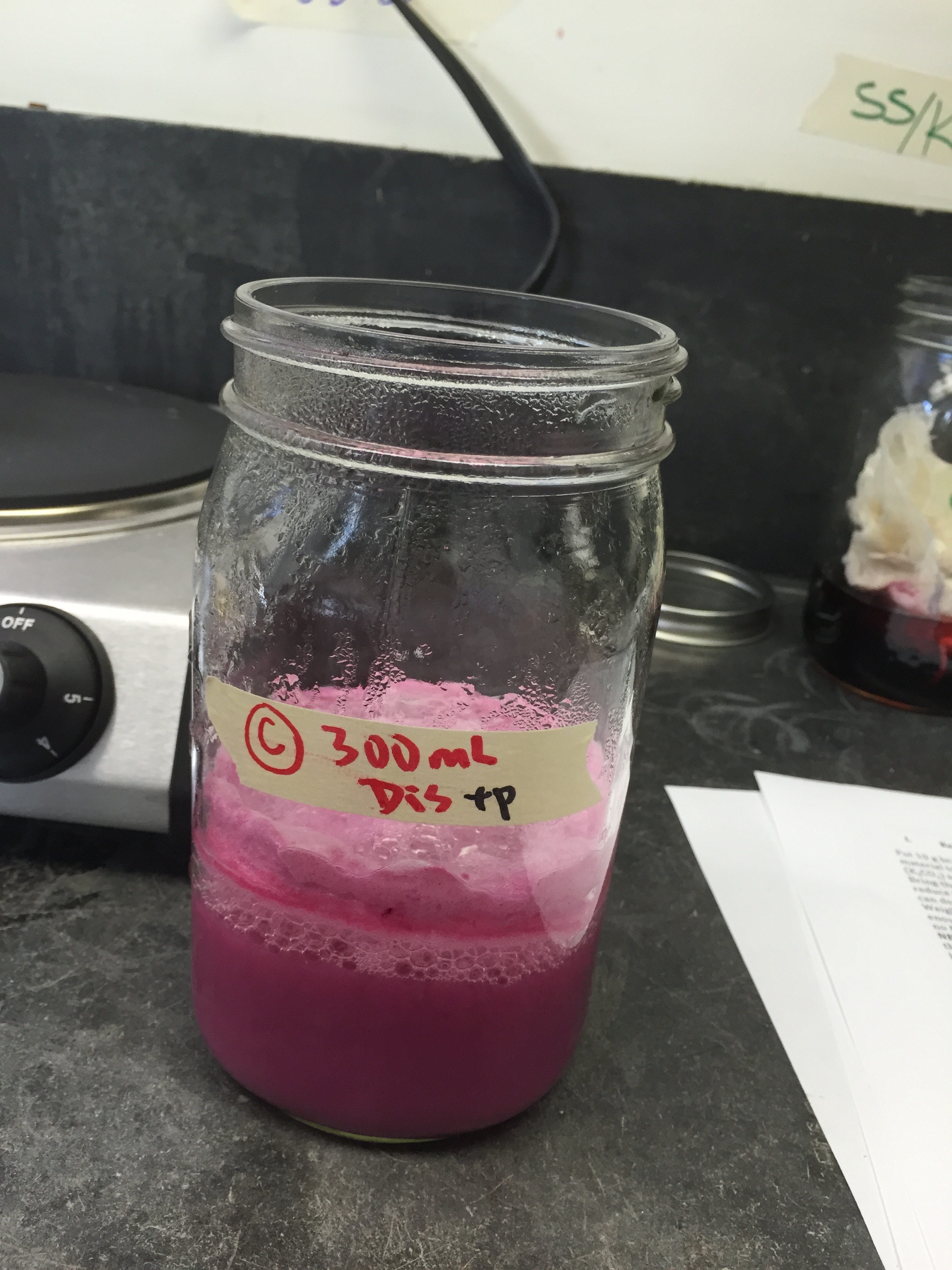

Noticed solids forming on top of cochineal solution

10:46am

Cochineal solution is at 65 degrees Celsius

10:53am

Water bath is boiling

10:54am

Cochineal is at 76 degrees Celsius and climbing

11:02am

Cochineal is at 80 degrees Celsius

11:04am

Turned heat up to 5

Concerned that cochineal solution may not boil in that heat is already turned all the way up

11:06am

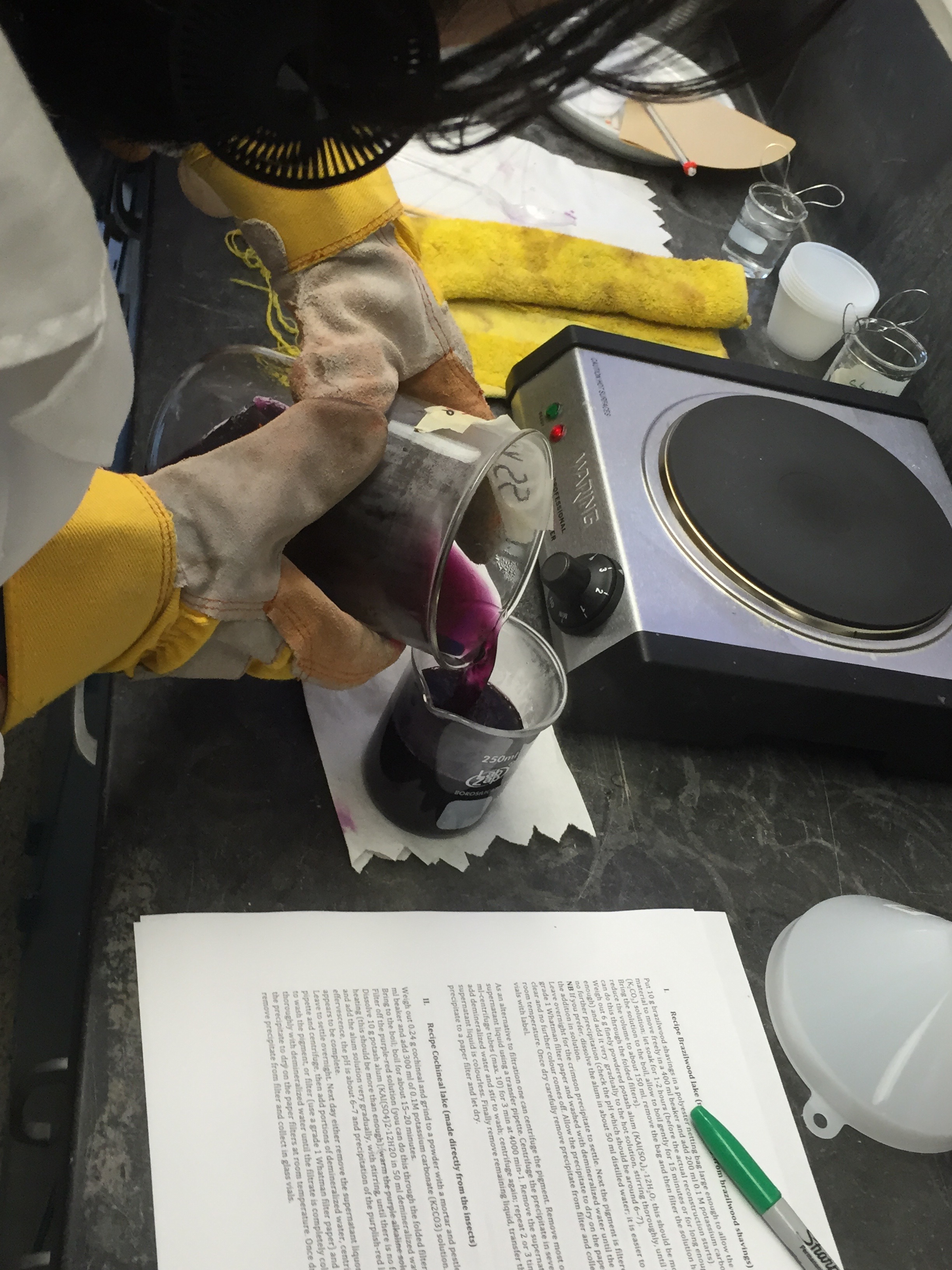

Transferring cochineal solution to a beaker and removing from water bath to be directly on hot plate (having turned temperature off for a second) in the hopes of boiling

The solution has already cooked down a bit because we now have just over 500ml (combined original solution [SSKK + Cindy/ Yuan] was originally 600ml)

Put beaker on TURNED OFF hot plate

Plan to heat directly on hot plate for five minutes in the hopes of boiling

11:09am

Cochineal solution is 76 degrees Celsius with hot plate TURNED OFF

11:12am

Turned hot plate back on?

Cochineal solution is at 77 degrees Celsius

11:19am

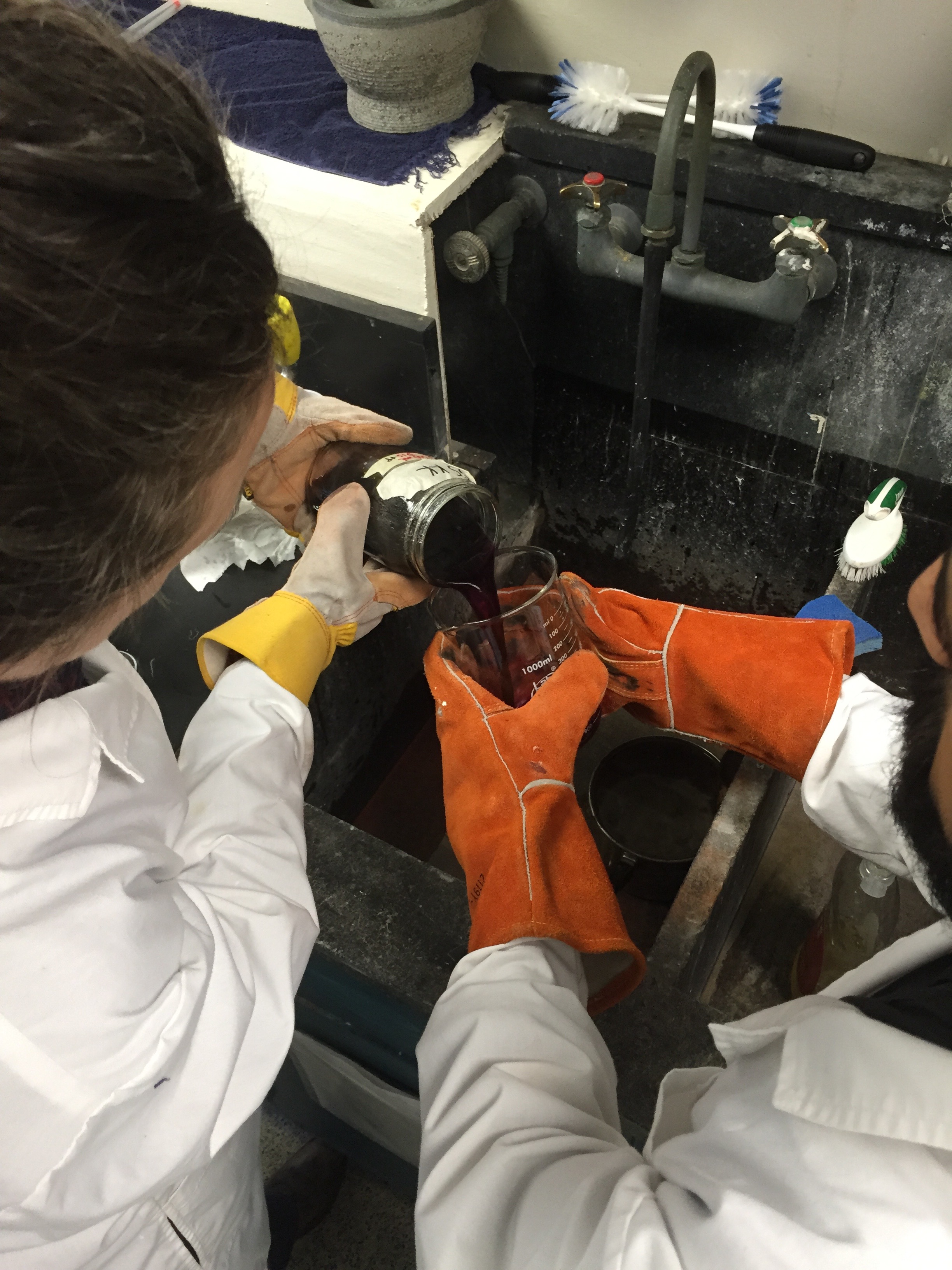

Splitting solution into 250ml each in the hopes that two beakers with solution will boil faster than one large beaker

11:28am

Rolling boil of cochineal solution in larger beaker, smaller beaker is beginning to bubble

11:32am

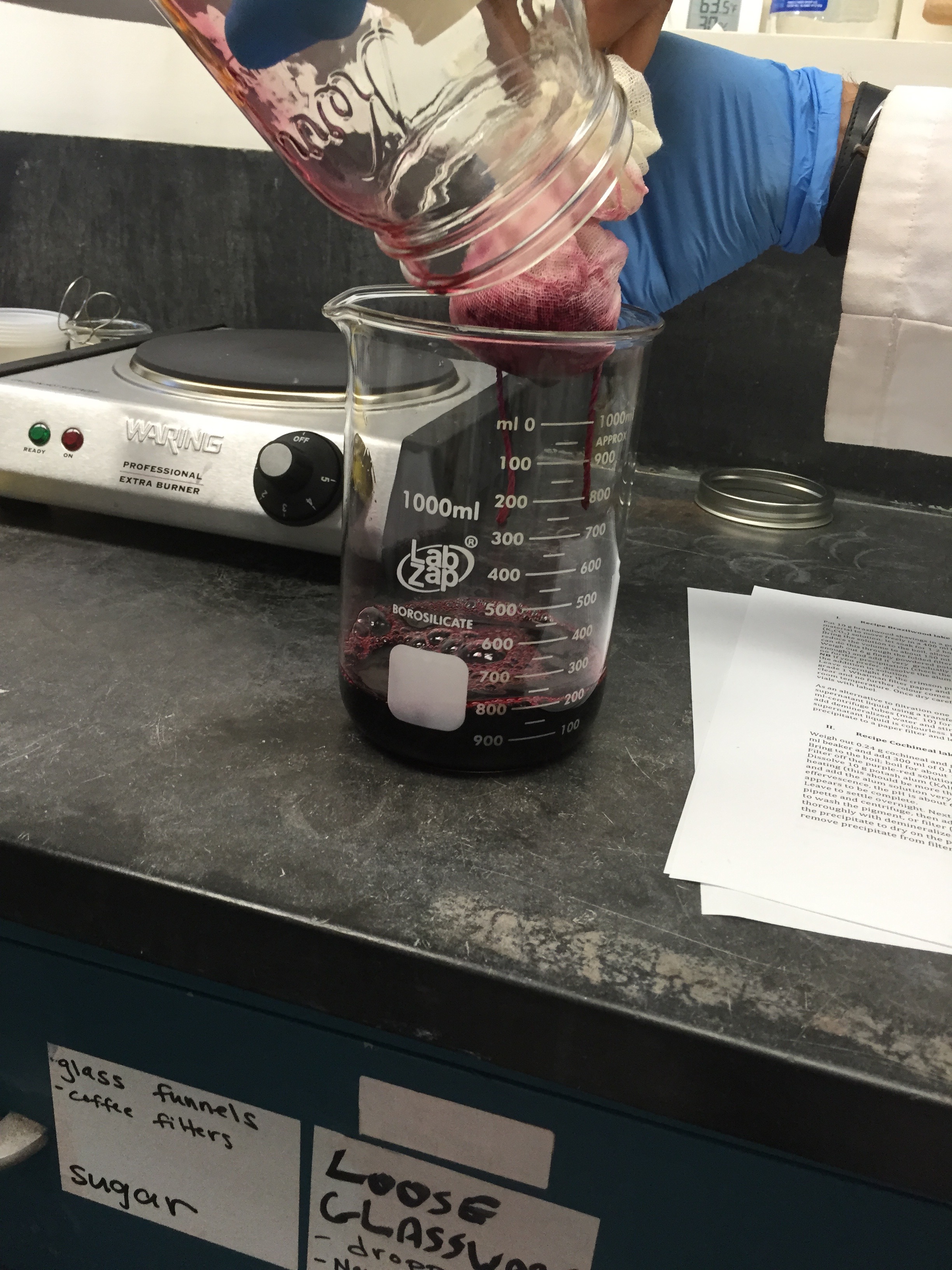

Slowly filtering our (smaller beaker) solution

11:34am

Put potash back on heat for a bit to re-dissolve some particles that had formed or had not originally dissolved

11:35am

Cochineal is at 65 degrees Celsius

11:38am

Slowly poured in potash solution (drop by drop) to cochineal solution while stirring; achieved effervescence

11:41am

Tested pH – was at 4, slightly acidic – decided to retest pH

11:42am

pH is at “6” – this is usable

Cochineal solution smelled like ammonium

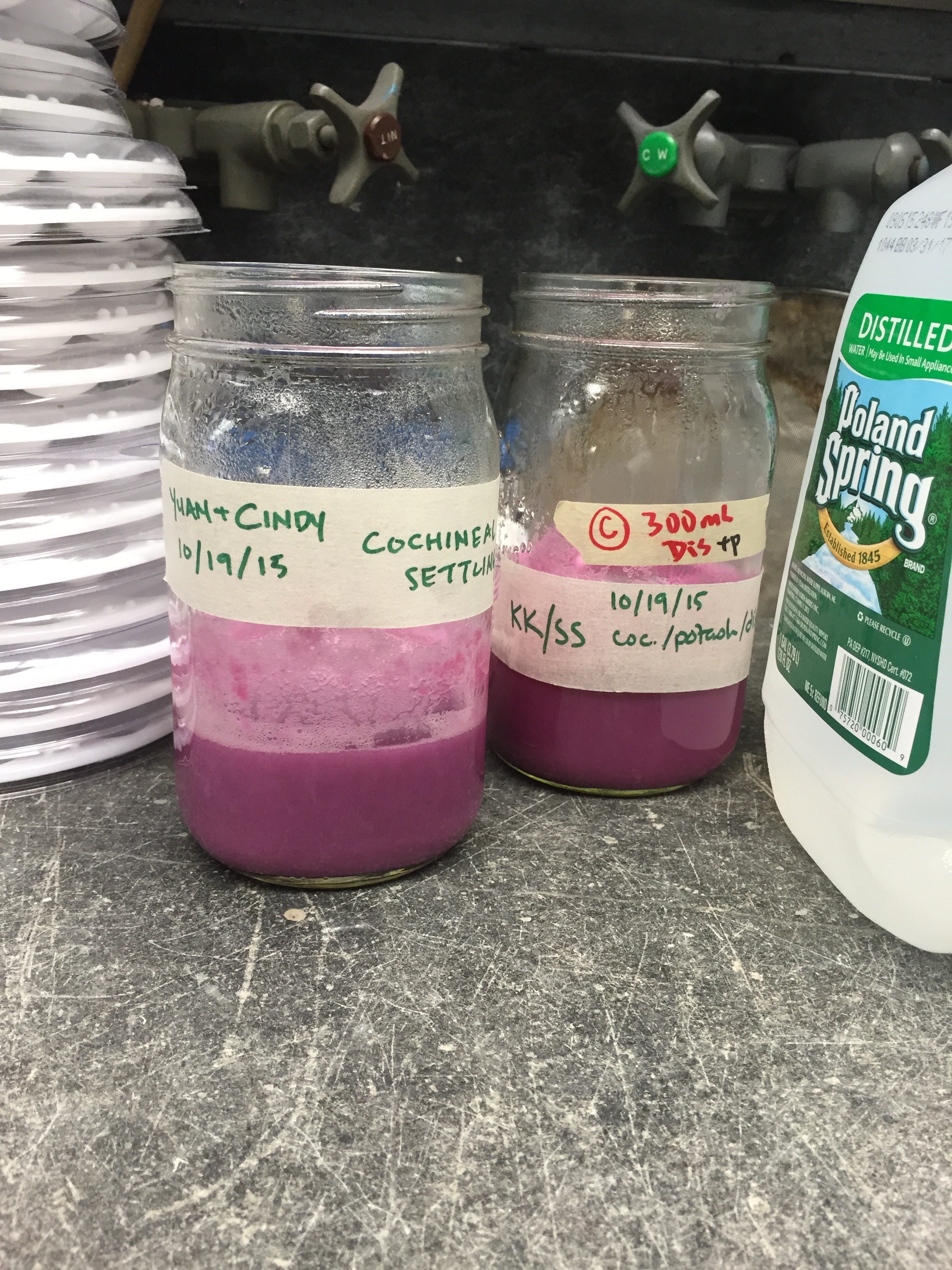

Our cochineal compared to Cindy and Yuan’s cochineal (below)

Cochineal would dissolve in either oil or egg so we are precipitating color onto aluminum in order to retain color

BRAZILWOOD

11:44am

Put brazilwood sachet and solution into a beaker to put on hot plate at 3

11:50am

Brazilwood solution is 51 degrees Celsius

11:51am

Increased heat to 4

11:53am

Dissolved 6g of potash alum into 50 ml of distilled water to more easily control pouring into brazilwood

11:56am

Brazilwood solution slight boiling

Smelled more pleasant that cochineal – more like plant

11:59am

Reduced temperature to 2

12:00pm

Reduced temperature to 1

12:01pm

Solution is at 150ml

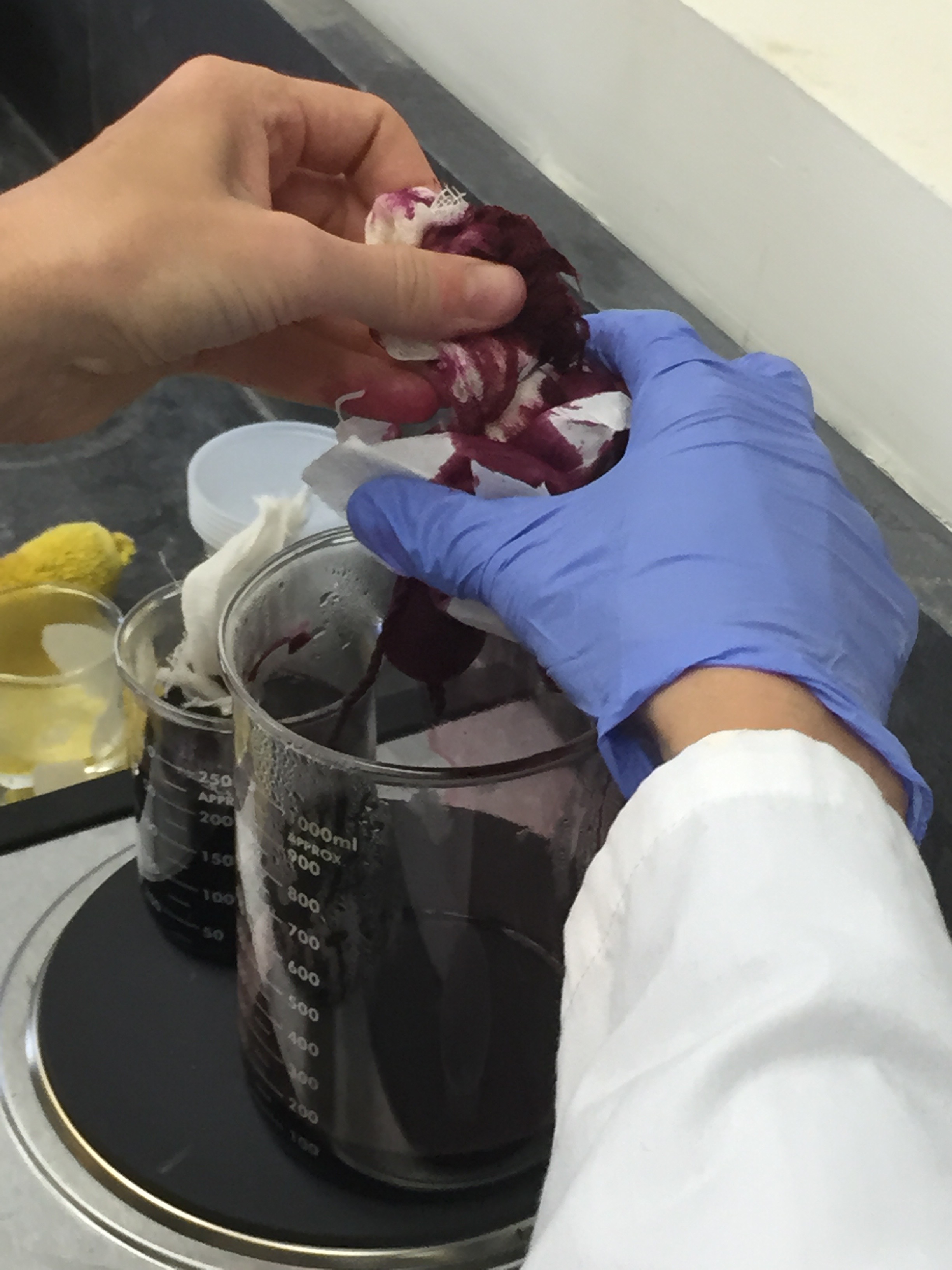

Removing sachet and squeezing out solution

12:04pm

Poured solution through filter/funnel into jar

12:05pm

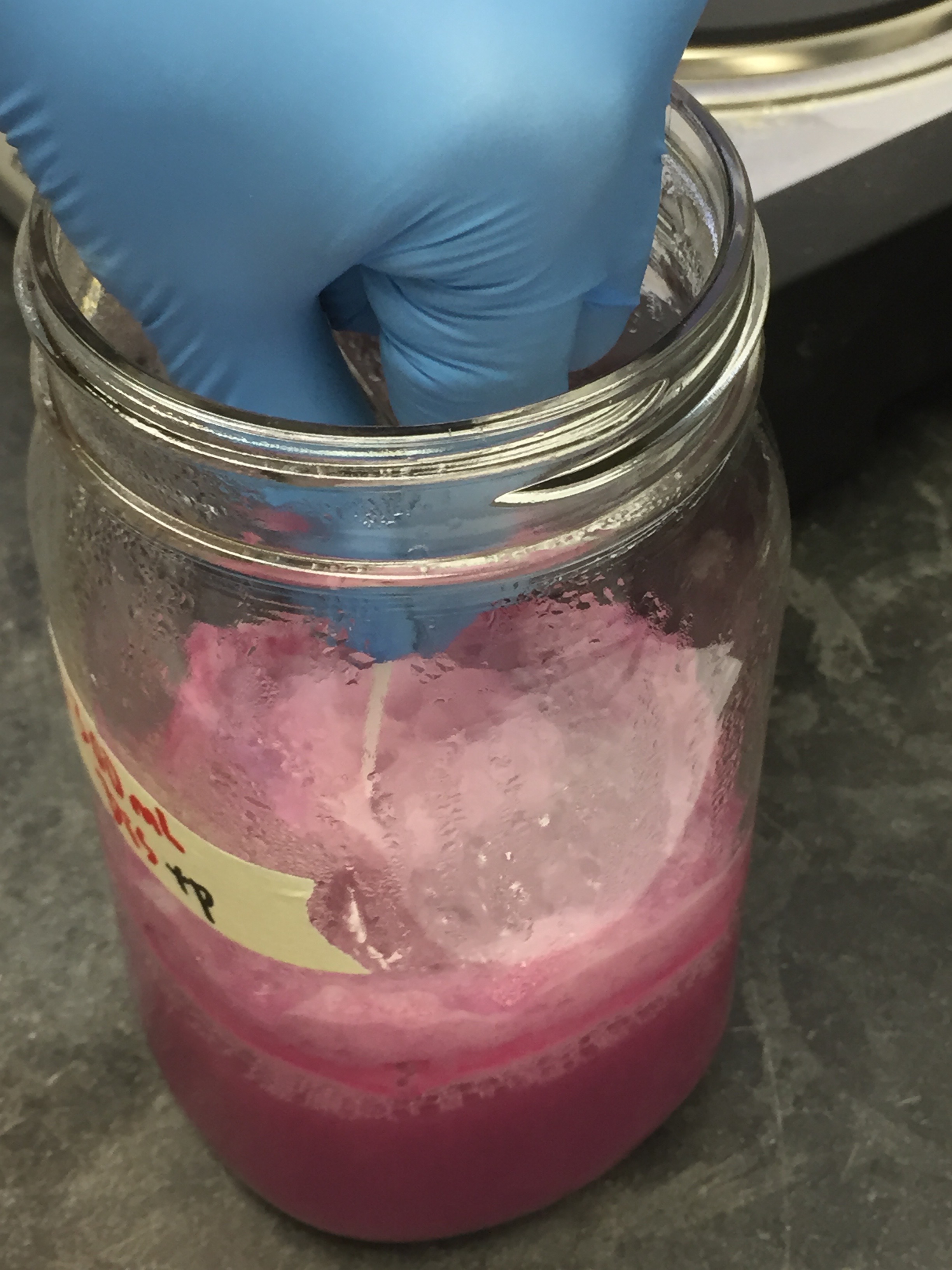

Stirring solution while pouring in potash solution; achieved effervescing; shook solution to get scum off edge

Color is very red, not “beet red”

Foam seems to be more solid than cochineal solution’s foam

FILTERING

Cochineal with distilled water

Normally leave cochineal to settle but Glasgow told us that the brazilwood doesn't really settle out very much so we might as well pour it (slowly) through filter, leave it filtering over night. Probably the case with the logwood too. What difference does filtering today and letting it sit overnight versus letting it sit overnight and filtering do? (PS)

Leave brazilwood solution from earlier to settle

1:18pm

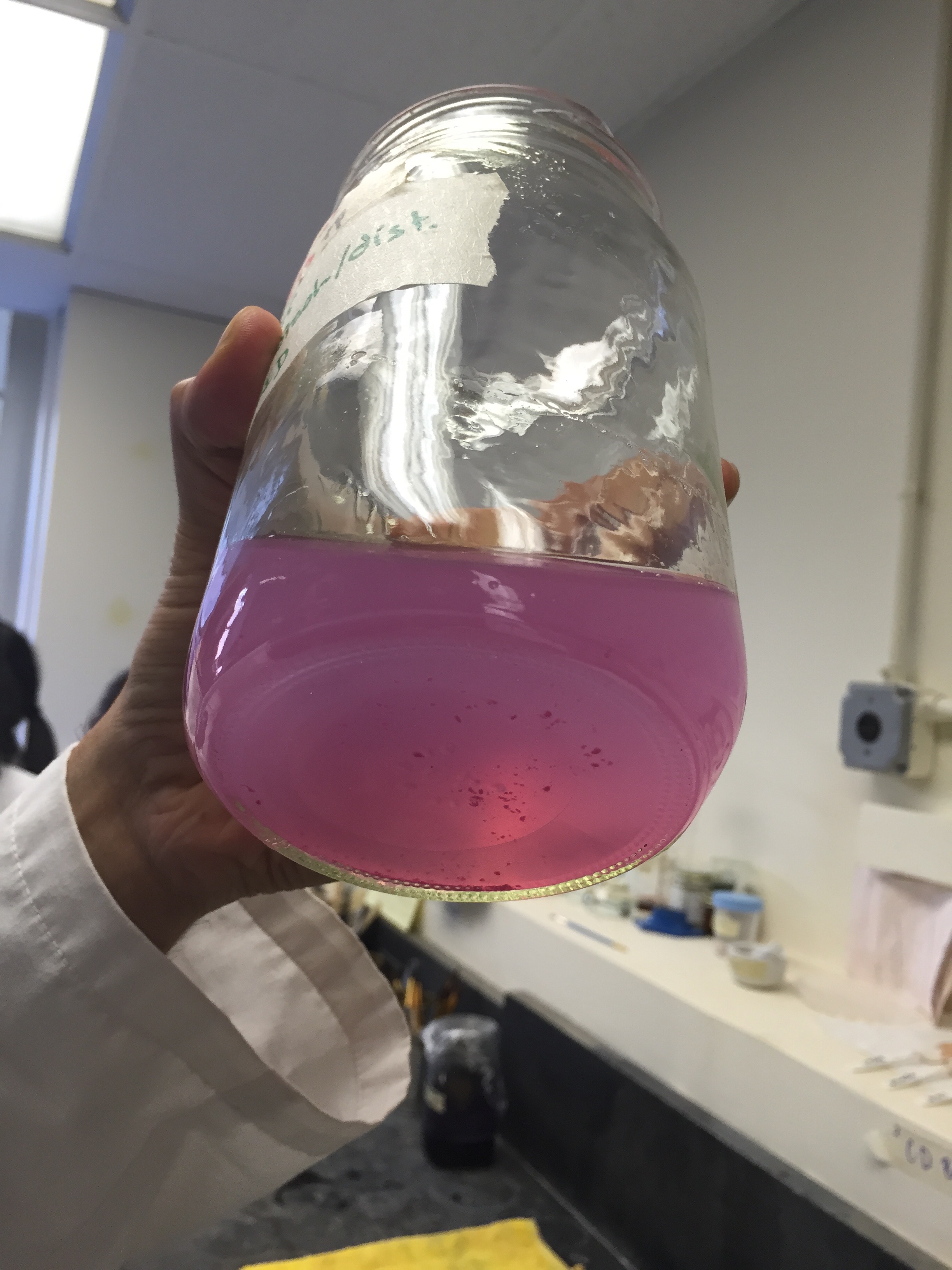

Filter: Poured solution of cochineal and distilled water + potash into jar through filter and funnel

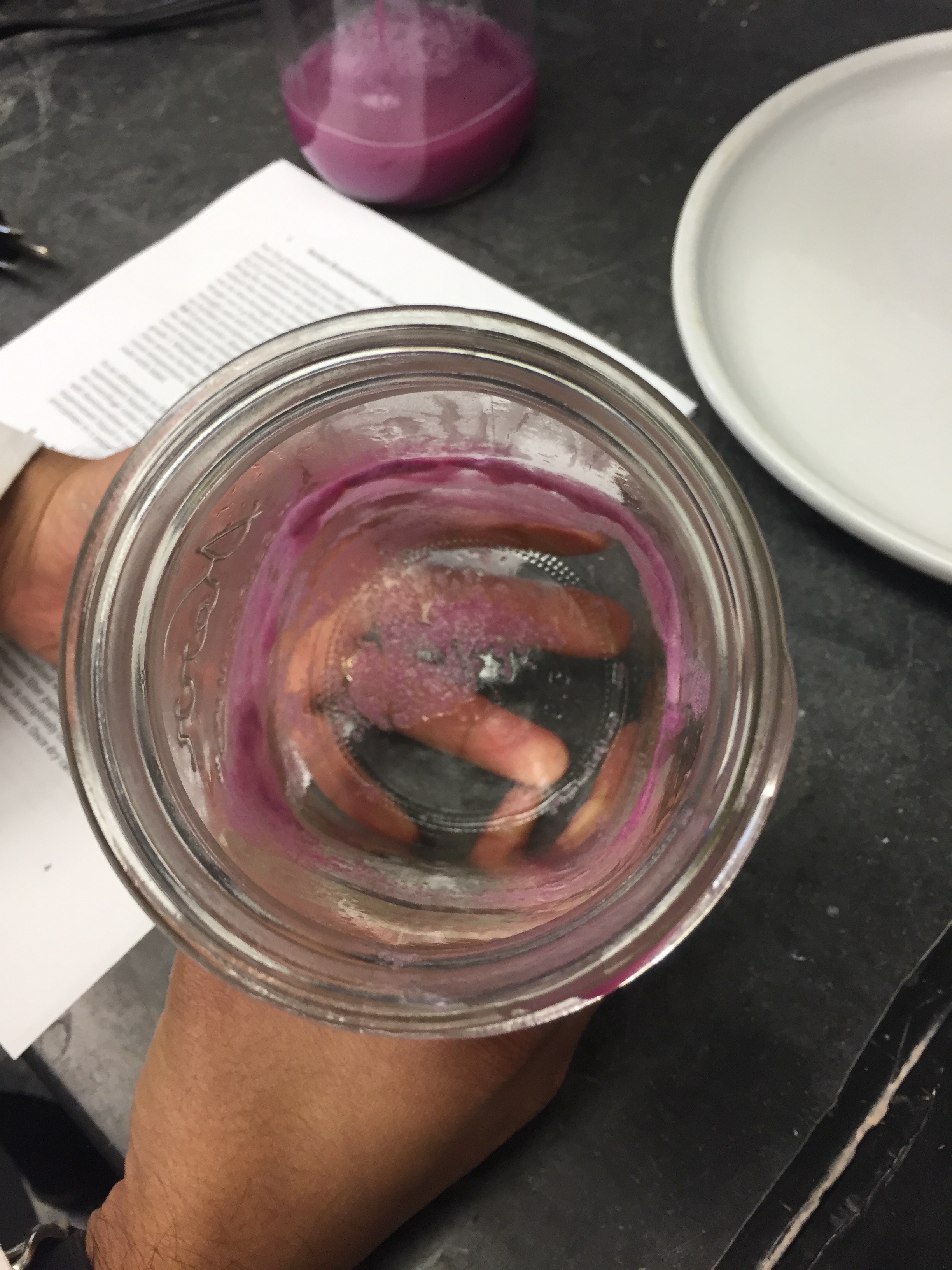

At first, quite liquidly, then more viscous and opaque sediment in bright magenta color

1:24pm

Emptying jar with filtered liquid

Plan to wash pigment as many times as necessary with distilled water until filtering clear

1:26pm

1st wash with 250ml of distilled water

MISTAKENLY washed sediment down the drain sediment

1:27pm

2nd wash with 100 ml of distilled water

Solution was filtering too quickly, prompted us to look for a hole – Siddhartha noticed small tear

1:31PM

Pouring filtered solution through lab grade filter paper in a separate funnel – filtering completely clear. From this, we decide that our pigment is thoroughly washed.

Pouring filtered solution through coffee filter in separate jar as well – lab grade filter is filtering better than coffee filter – liquid is totally clear as opposed to coffee filter jar which is slightly pink but still quite clear

Found that pouring liquid not directly on center, rather down side, may be a more sensitive way to filter re: weight of solution, pressure, etc.

Filtering the twice filtered refuse again through lab grade filter paper – filtering totally clear

BRAZILWOOD + DIST. WATER +POTASH FILTERING:

20.10.2015

Lab

4:35pm

Filter

21.10.2015

Lab

12:30pm

1st wash

1:00pm

2nd wash

1:50pm

3rd wash

2:05pm

4th wash

2:45pm

5th wash

3:30pm

6th wash

22.10.2015

Lab

2:42pm

7th wash

2:58pm

8th wash

(photos mid-wash, did not note at which wash these were taken)